product description

Air Cooled Screw Chiller

The air cooled screw chiller is an efficient and reliable industrial cooling unit, with its main components utilizing a screw compressor, hence it is referred to as an air-cooled screw chiller. It employs a combination of screw compression and air-cooled heat dissipation, providing excellent refrigeration capacity and stable performance. This chiller does not require an additional cooling water source or cooling tower. Instead, it utilizes built-in fans to dissipate the heat from the condenser into the surrounding air, achieving efficient cooling effects.

As an ideal choice in the field of industrial cooling, our air-cooled screw chiller offers outstanding cooling solutions to our customers, characterized by high efficiency, energy-saving operation, and dependable performance.

| Application Scope in the Industry

The air cooled screw chiller is suitable for a wide range of industrial applications. It can precisely control temperatures ranging from 3°C to 50°C, meeting the requirements of various industries such as plastics (injection molding, extrusion), plastic packaging, automotive manufacturing, electronics manufacturing, electroplating, pharmaceuticals, chemical industry, ultrasonic cooling, printing, and more. Whether it's cooling needs in plastic processing or temperature control in other production processes, the air-cooled screw chiller can provide stable and reliable cooling effects, ensuring the normal operation of equipment and processes.

| Highlights of the Product

Semi-hermetic Screw Compressor

With low noise and vibration levels, it achieves energy savings of over 20%.

Air cooled screw compressor utilizes a semi-hermetic screw compressor, offering advantages such as stability, reliability, low noise, and low vibration. During the compression process, gas enters the compression chamber from the suction end of the screw, and as the screw rotates, the gas is gradually compressed and eventually discharged through the exhaust end. The thread shape and rotational motion of the screw ensure the continuity and stability of the gas during the compression process. Zhejiang or Han Zhong, two globally renowned brands, provide the screw compressors used in the Xiecheng water-cooled screw compressor, ensuring long-lasting, efficient, and stable operation. Compared to traditional scroll compressors, it achieves energy savings of over 20%, resulting in more energy-efficient operation.

Features::1、20% Energy Saving 2、low Noise 3、Low Vibration

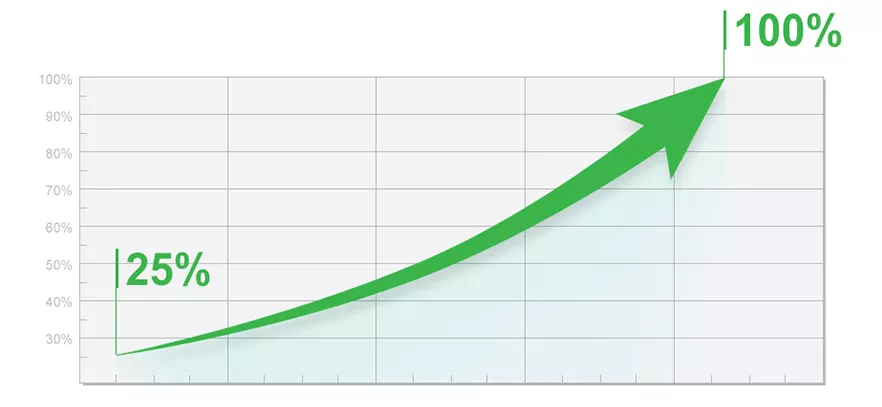

| Stepless Capacity from 25% to 100%

Screw compressors feature stepless capacity control, which means that a single compressor can continuously adjust the cooling capacity in any range between 25% to 100%. This allows for precise control of energy output, ensuring stable and efficient operation.

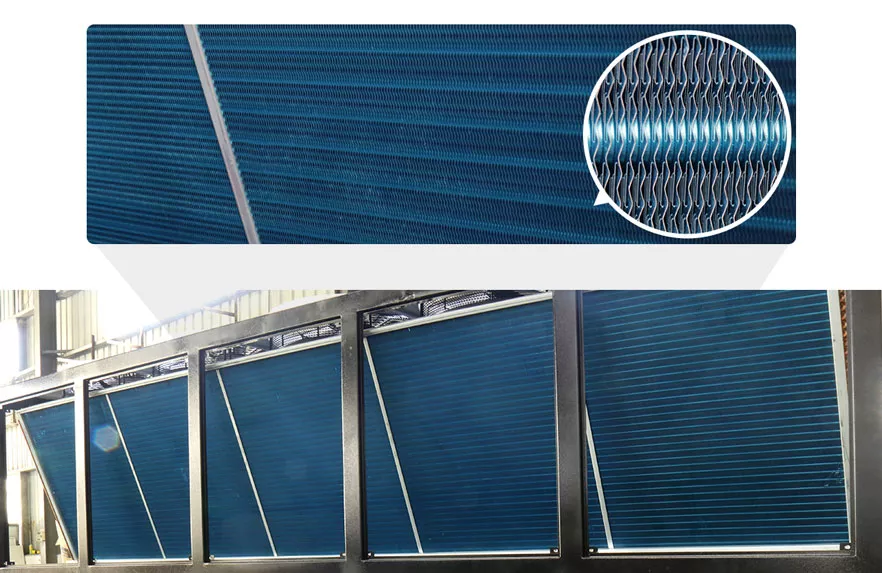

| Fin Type Condenser

By adopting a high-efficiency copper tube with aluminum finned type condenser, the air cooled chiller effectively dissipates heat. The finned structure increases the heat exchange surface area between the condenser and the surrounding environment, improving the heat dissipation efficiency. The excellent thermal conductivity of copper tubes, combined with the efficient heat dissipation characteristics of aluminum fins, ensures high efficiency during the cooling process.

Additionally, the application of light water aluminum and blue aluminum foils provides an additional protective layer. They help prevent corrosion of the copper tubes in corrosive environments, thereby extending the lifespan of the condenser and maintaining optimal refrigeration performance.

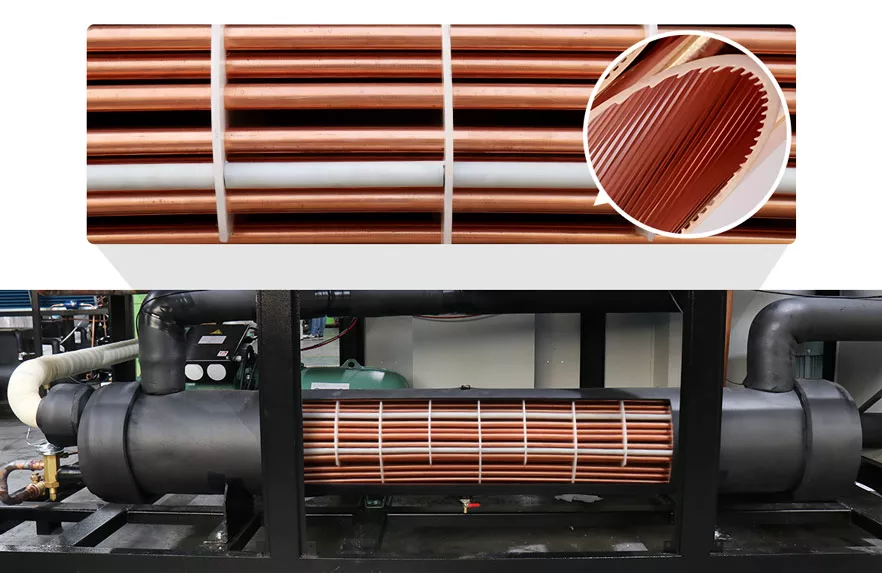

| Shell and Tube Evaporator

The Water Cooled Screw Chiller utilizes a shell and tube evaporator. In this system, the refrigerant evaporates inside the heat exchange tubes, while water flows on the shell side. To enhance the heat exchange efficiency, a 2mm thick baffle plate is installed on the shell side, causing the water to flow back and forth to create ice brine. Additionally, to maintain a stable operating temperature, the exterior shell of the evaporator is covered with insulation material.。

For the heat exchange tubes, we employ high-efficiency seamless copper tubes. These tubes undergo a grooving process to form internal thread fins, thereby increasing the heat exchange surface area with the refrigerant. With this technology, the heat transfer area is doubled, significantly improving the heat transfer efficiency.

| Product Details

| Specifications

|

Model |

UNIT |

XC-LF40AS |

XC-LF50AS |

XC-LF60AS |

XC-LF80AS |

XC-LF100AS |

|

|

Refrigerating capacity |

kw |

125 |

165.2 |

176 |

237.2 |

330 |

|

|

kcal/h |

107500 |

142072 |

151360 |

203992 |

283800 |

||

|

Input Power |

Kw |

30 |

37 |

45 |

30x2 |

37x2 |

|

|

Control type |

Expansion valve |

||||||

|

Refrigerant |

R22(R407C) |

||||||

|

Compressor |

Type |

Semi-hermetic Screw |

|||||

|

Quantity |

1/2/3/4 |

||||||

|

Startup mode |

Y-△ |

||||||

|

Capacity control(%) |

0-25-50-75-100 |

||||||

|

Power |

3PH-380V/50HZ(200V/220V/415V 50HZ/60HZ) |

||||||

|

Evaporator |

Type |

Shell and tube type |

|||||

|

Cooling water flow(m3/h) |

18 |

23 |

26 |

26 |

46 |

||

|

Inet and outlet pipe caliber(Inch) |

3" |

3" |

3" |

4" |

4" |

||

|

Condenser |

Type |

Air cooled high-efficient inner threaded copper- tubing aluminum fin type |

|||||

|

Fan |

Type |

low noise orter rotor high power axial fan |

|||||

|

Power(Kw) |

2.4 |

4.8 |

9 |

4.8 |

18 |

||

|

Cooling air flowm(3/hr) |

40000 |

51000 |

63000 |

80000 |

105000 |

||

|

Safety protector |

Compressor over heat/Over loading/High and low pressure/Over temperature/Phase and phase reverse/Anti freezing |

||||||

|

Dimensions(L*W*H) |

mm |

2150x2000x1850 |

2400x2250x1880 |

2480x2300x1980 |

2600x2300x1980 |

4050x2100x2020 |

|

|

NetWeight |

KG |

1300 |

1620 |

1930 |

2260 |

3340 |

|

|

Model |

UNIT |

XC-LF120AS |

XC-LF160AS |

XC-LF180AS |

XC-LF200AS |

XC-LF240AS |

|

|

Refrigerating capacity |

kw |

353.2 |

473.4 |

556.3 |

655 |

767 |

|

|

kcal/h |

303752 |

407124 |

478418 |

563300 |

659620 |

||

|

Input Power |

Kw |

45x2 |

60x2 |

67x2 |

75x2 |

90x2 |

|

|

Control type |

Expansion valve |

||||||

|

Refrigerant |

R22(R407C) |

||||||

|

Compressor |

Type |

Semi-hermetic Screw |

|||||

|

Quantity |

1/2/3/4 |

||||||

|

Startup mode |

Y-△ |

||||||

|

Capacity control(%) |

0-25-50-75-100 |

||||||

|

Power |

3PH-380V/50HZ(200V/220V/415V 50HZ/60HZ) |

||||||

|

Evaporator |

Type |

Shell and tube type |

|||||

|

Cooling water flow(m3/h) |

52 |

71 |

86 |

100 |

117 |

||

|

Inet and outlet pipe caliber(Inch) |

4" |

4" |

6" |

6" |

6" |

||

|

Condenser |

Type |

空气冷却式高效铜管套铝 air cooled high-efficient inner threaded copper- tubing aluminum fin type |

|||||

|

Fan |

Type |

大功率轴流风机 low noise orter rotor high power axial fan |

|||||

|

Power(Kw) |

18 |

27 |

27 |

36 |

36 |

||

|

cooling air flow(m3/hr) |

122000 |

155000 |

175000 |

205000 |

250000 |

||

|

Safety protector |

|||||||

|

Dimensions(L*W*H) |

mm |

4550x2100x2155 |

2400x3400x1880 |

3150x4200x2200 |

2600x4550x1980 |

4050x4200x2050 |

|

|

NetWeight |

KG |

3850 |

4200 |

4450 |

4670 |

4860 |

|