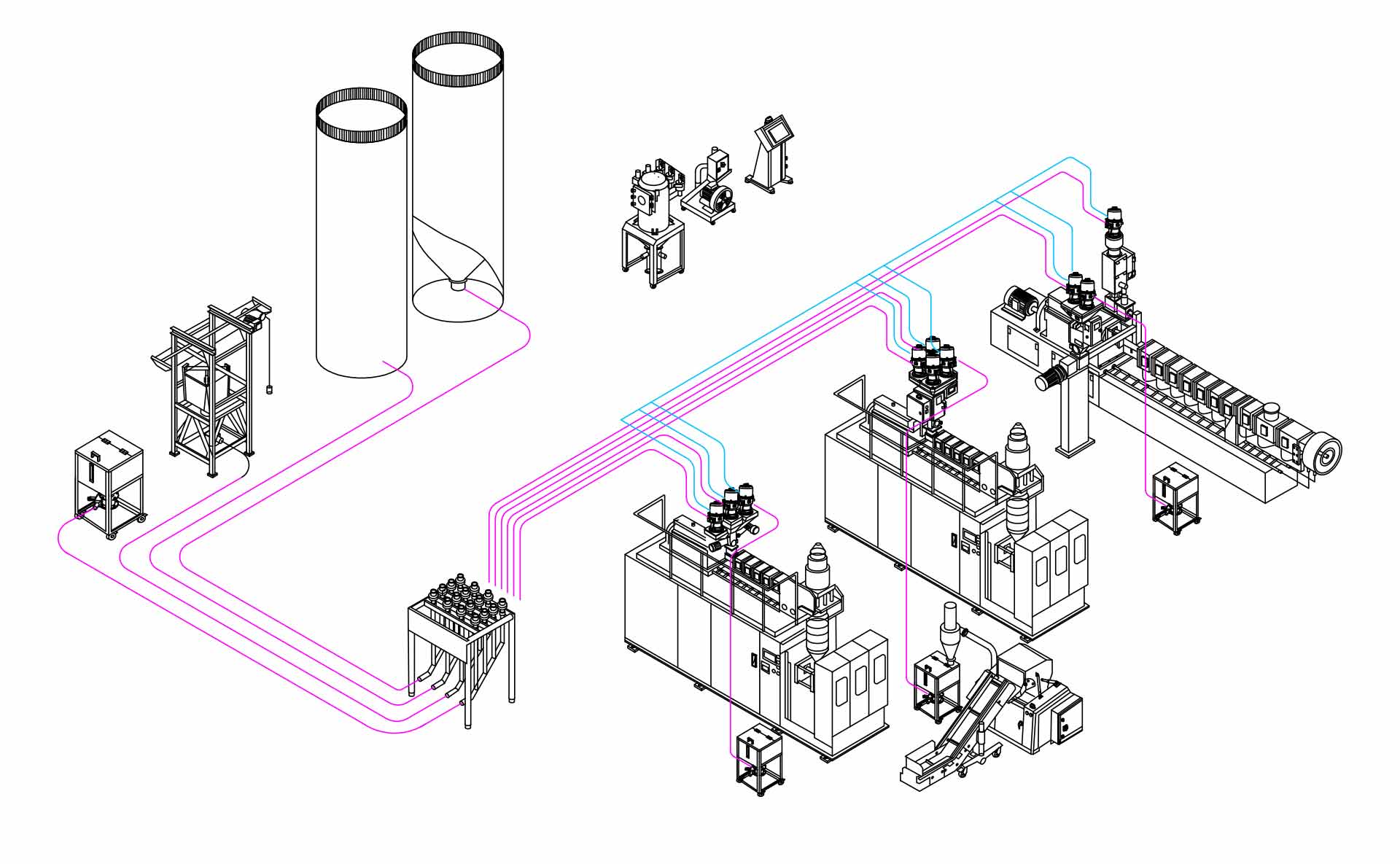

Extrusion Blow Molding System

Extrusion Blow Molding System

|

The blow molding process consists of two main blow molding methods, extrusion blow molding and injection blow molding. Place a tubular plastic parison, obtained by extrusion or injection molding of a thermoplastic resin, into a split mold while being heated (or heated to a softened state), and import compressed air into the parison immediately after closing the mold to inflate the plastic parison and make it adhere closely to the inner wall of the mold, finally after the cooling and demoulding, we would get all kinds of hollow products. Blow molding is a molding process in manufacturing hollow thin-walled products from thermoplastic materials. Typical products are large-capacity final consuming products such as bottles and containers. At present, the most widely used plastics in production are PE, PP and PVC.

|

|

13 มิถุนายน 2565

ผู้ชม 616 ครั้ง