Flake Type Plastic Granulator

16 ธันวาคม 2567

ผู้ชม 103 ผู้ชม

Product Description

Flake Type Plastic Crusher

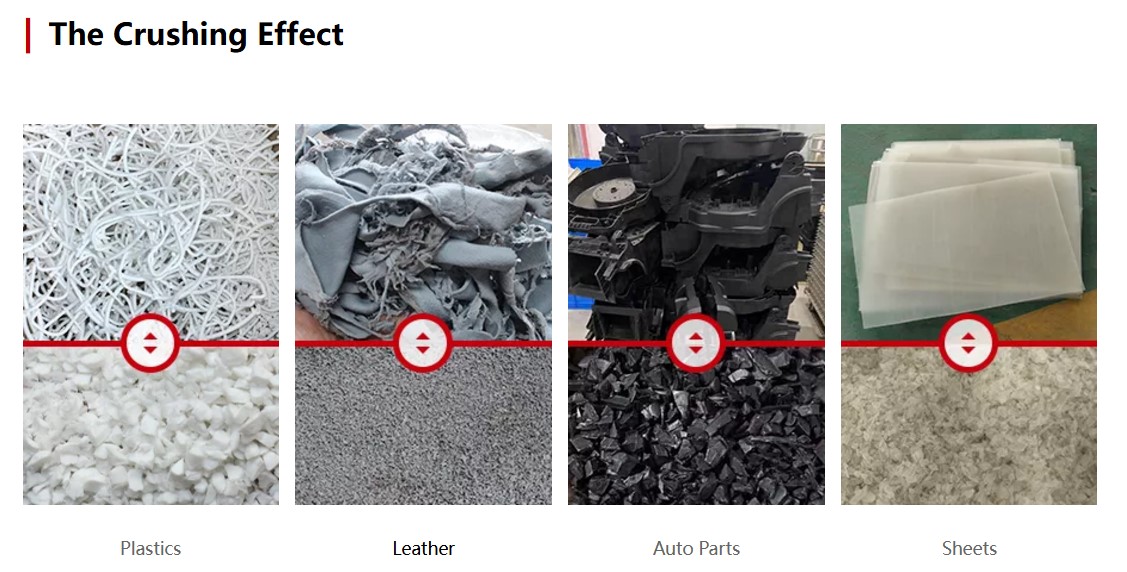

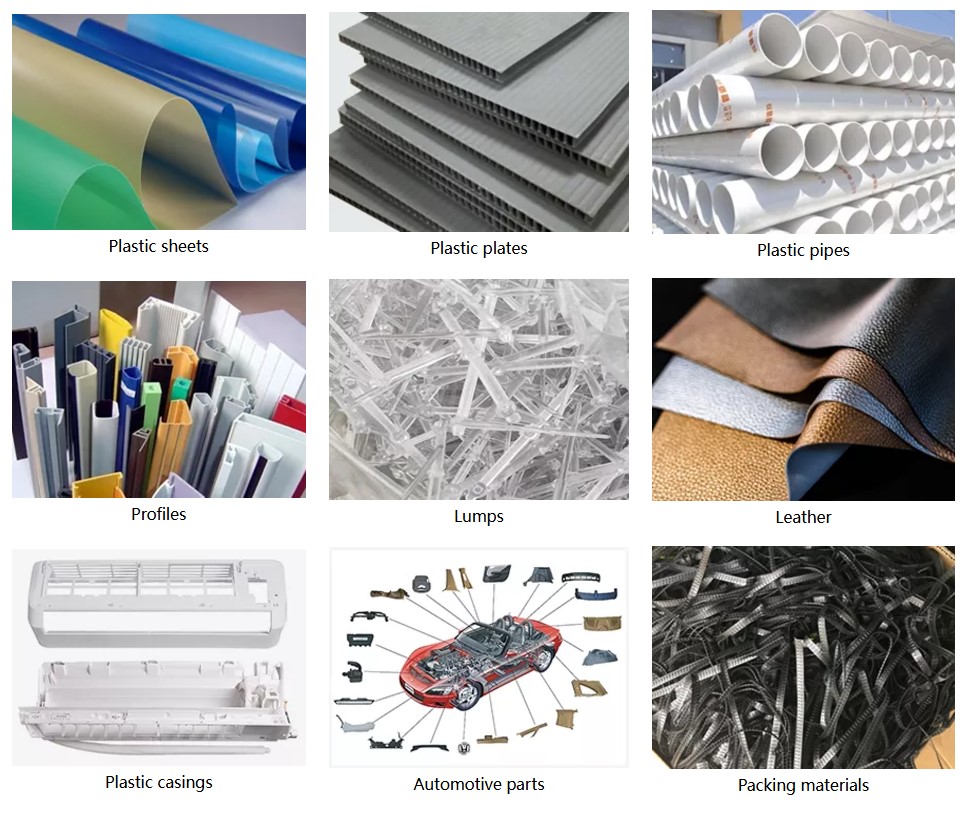

The Xiecheng GP Flake Type Plastic Crusher, also known as a universal plastic granulator, features a unique blade holder design that falls between a claw blade and a flat blade. It is suitable for shredding various plastic products, including common sheets, pipes, profiles, sheets, and packaging materials. It is also applicable for processing sprue materials. The crusher finds wide applications in plastic molding processes such as injection molding, extrusion, blow molding, as well as in plastic recycling and utilization.

The Flake Type Plastic Crusher exhibits stable and efficient crushing capabilities. It can grind waste plastic into desired particle sizes, with uniform particle shapes and minimal powder content. It provides a reliable solution for plastic recycling and reuse, helping to improve the utilization of waste plastic and meet various processing and utilization needs.

| Features of the GP Series

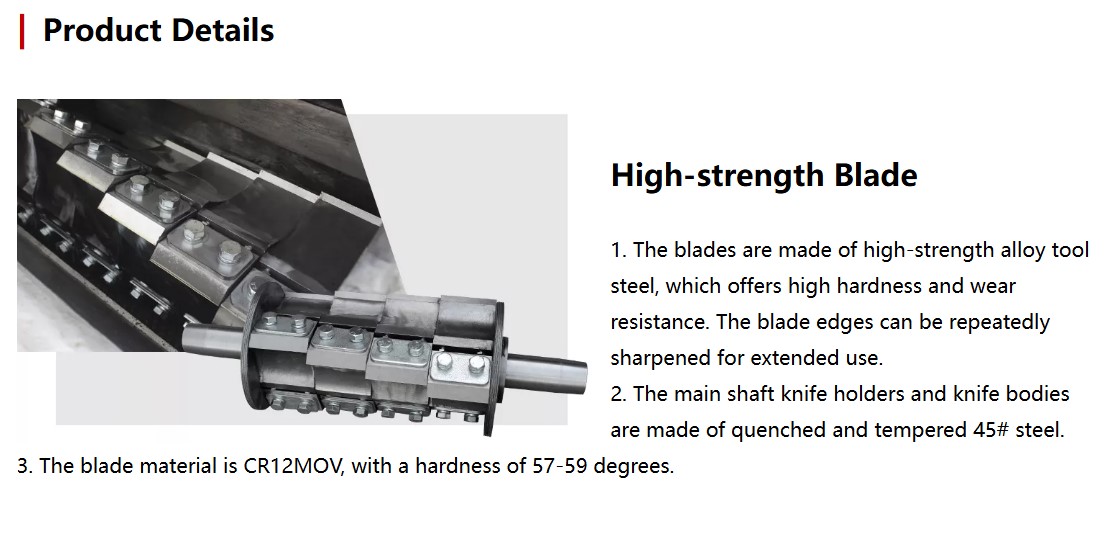

1. The blade holder falls between a claw blade and a flat blade, providing a versatile cutting solution.

2. Double-layer soundproofing design before and after the feeding area, ensuring excellent noise reduction performance.

3. The blades are made of high-strength alloy tool steel (Cr12mov).

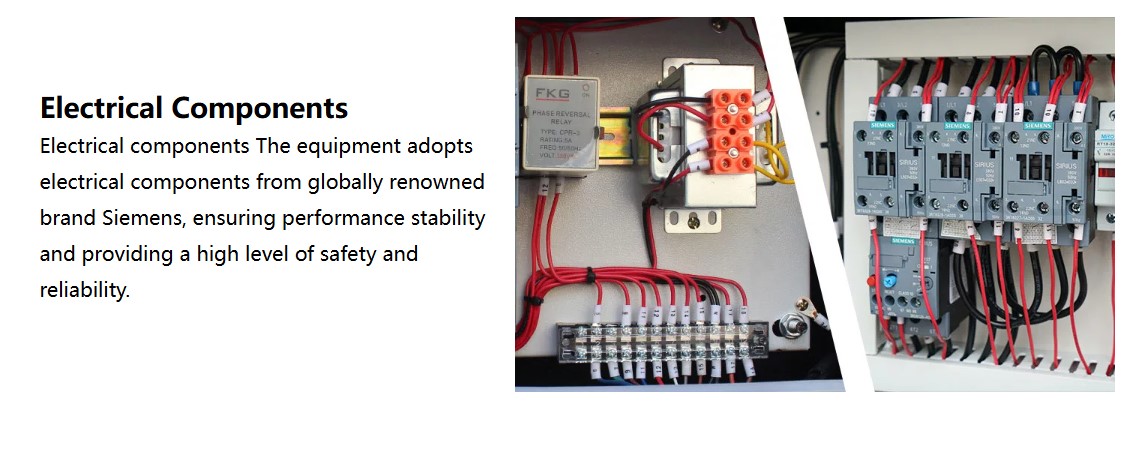

4. Equipped with renowned Siemens electrical components, ensuring reliable performance.

5. Suitable for shredding common sheet materials and various plastic sprue materials.

| Crushing Process Material

The flake-type plastic crusher is capable of shredding various plastic products, including common sheets, pipes, profiles, plates, and packaging materials. It can also handle sprue materials such as runners, edge trim, circuit boards, automotive parts, bumpers, computer keyboards, air conditioner casings, aluminum composite panels, cable sheaths, LED strips, and more. The versatility of the blade-type plastic crusher makes it suitable for a wide range of plastic materials and applications.

| Specifications of GP Series

|

Model |

XC-GP230 |

XC-GP300 |

XC-GP400 |

XC-GP500 |

XC-GP600 |

XC-GP800 |

XC-GP960 |

XC-GP1100 |

XC-GP1200 |

|

|

XC-GP230-SP |

XC-GP300-SP |

XC-GP400-SP |

XC-GP500-SP |

XC-GP600-SP |

XC-GP800-SP |

XC-GP960-SP |

XC-GP1100-SP |

XC-GP1200-SP |

||

|

Grinding Chamber(mm) |

230x200 |

310x200 |

410x240 |

510x300 |

610x330 |

815x470 |

960x610 |

1100x800 |

1200x800 |

|

|

Grinding Capacity (KG/H) |

100-150 |

150-200 |

200-250 |

300-350 |

350-450 |

450-600 |

800-1000 |

1000-1200 |

1000-1500 |

|

|

Stationary Cutter |

2 |

2 |

2 |

2 |

4 |

4 |

4 |

4 |

4 |

|

|

Rotary Cutter |

6 |

9 |

12 |

15 |

18 |

24 |

30 |

33 |

36 |

|

|

Mesh Size (mm) |

8 |

8 |

8 |

10 |

10 |

10 |

12 |

12 |

12 |

|

|

Power |

KW |

4 |

5.5 |

7.5 |

11 |

15 |

22/30 |

37/45/56 |

75 |

75 |

|

HP |

5 |

7.5 |

10 |

15 |

20 |

30/40 |

50/60/75 |

100 |

100 |

|

|

Dimensions (LxWxHxH1 mm) |

800x660 x1120 x875 |

920x725 x1200 x960 |

980x810 x1260 x985 |

1200x970 x1570 x1230 |

1200x1070 x1670 x1300 |

1600x1555 x2190 x1670 |

2000x1725 x2720 x2050 |

2420x2120 x3230 x2380 |

2420x2220 x3230 x2380 |

|

|

Approx. Net Weight (KG) |

277 |

420 |

500 |

805 |

940 |

2000 |

3000 |

6000 |

6500 |

|

|

Dimension for SP (mm) |

1020x730 x1320 x1075 |

1250x830 x1530 x1280 |

1350x930 x1590 x1320 |

1560x1070 x1784 x1440 |

1560x1170 x1870 x1500 |

1900x1510 x2460 x1940 |

2150x1794 x2990 x2320 |

2630x2180 x3600 x2760 |

2630x2280 x3600 x2760 |

|

|

Collective Blower (KW) |

2.2 |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

4/5.5 |

7.5 |

7.5 |

|

|

Approx. N.W for SP (KG) |

400 |

535 |

604 |

1220 |

1420 |

2380 |

3500 |

6500 |

6800 |

|

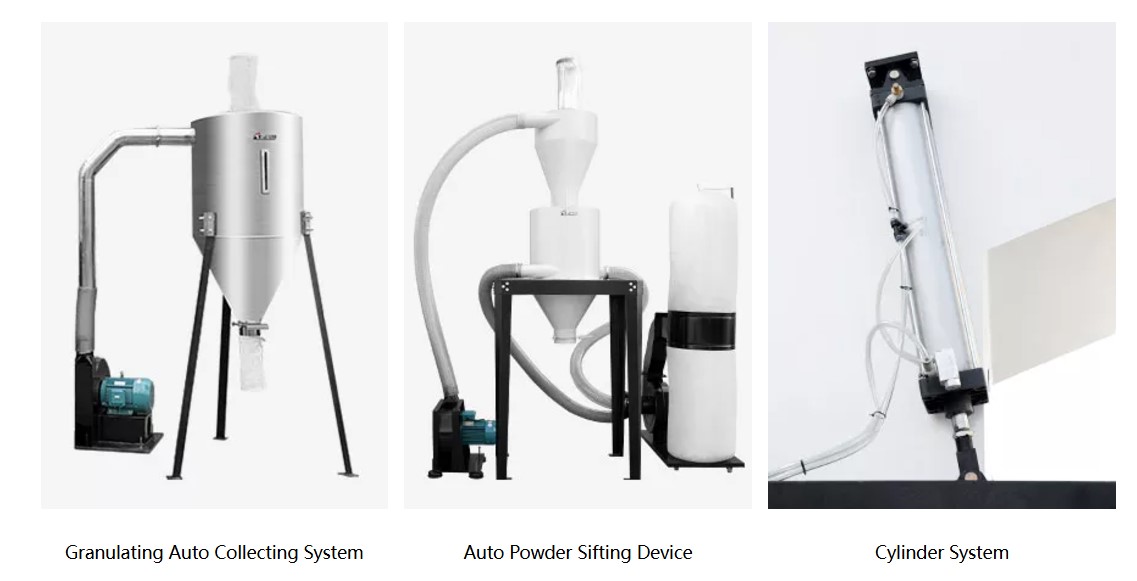

| Optional Accessories List

The Xiecheng flake type plastic crusher also offers flexible configuration options to meet the diverse needs of different users and achieve better crushing results and material collection. For models with a power of 75HP or above, the feeding hopper and screen frame support are equipped with a cylinder system, which is included as a standard configuration. For other models, you have the option to add or exclude this cylinder system based on your requirements. Additionally, automatic recycling and automatic powder screening systems are available as optional configurations to further enhance the functionality of the crusher.