Flat Type Plastic Granulator

16 ธันวาคม 2567

ผู้ชม 110 ผู้ชม

Product Description

Flat Type Plastic Crusher

The XIECHENG Flat Type Plastic Crusher is a plastic crushing machine designed specifically for various blow-molded parts, sprues, corner materials, and thin products. It utilizes a flat blade design with a wide cutting surface area and cutting force, enabling efficient crushing of these plastic products into the desired particles for convenient subsequent reuse and processing. It is suitable for plastic molding processes such as injection molding, extrusion, and blow molding, as well as for waste recycling. It can handle various plastic products such as plastic bottles, plastic bags, and plastic films. With its compact design and easy operation, it is an important piece of equipment in the field of plastic recycling and regeneration.

| Features of GD series

1. The front blade of the machine is designed with an increased cutting angle, resulting in high efficiency, uniform particle size, and minimal powder production.

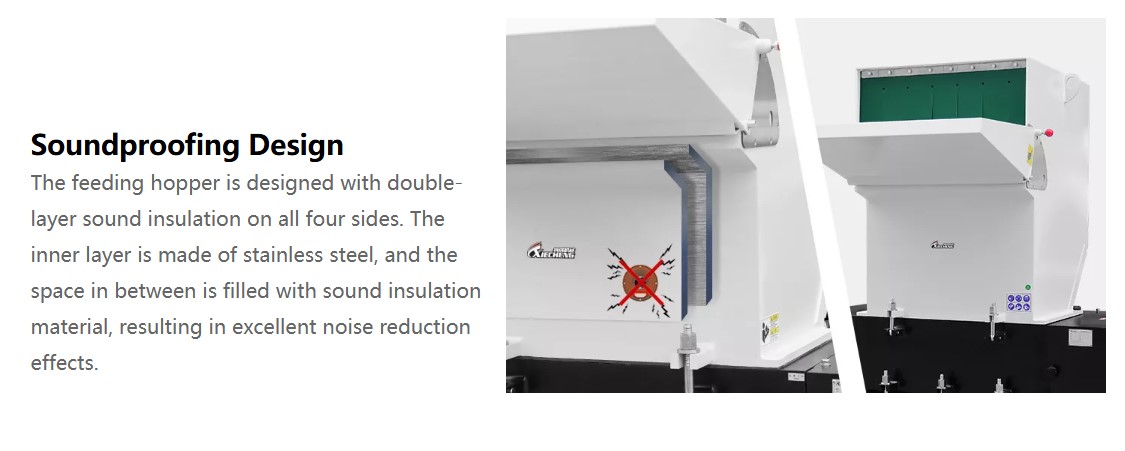

2. The machine is equipped with double-layer sound insulation on all four sides, providing excellent noise reduction.

3. The blades are made of high-strength alloy tool steel (Cr12mov).

4. It is suitable for various blow-molded parts, sprues, and thin products.

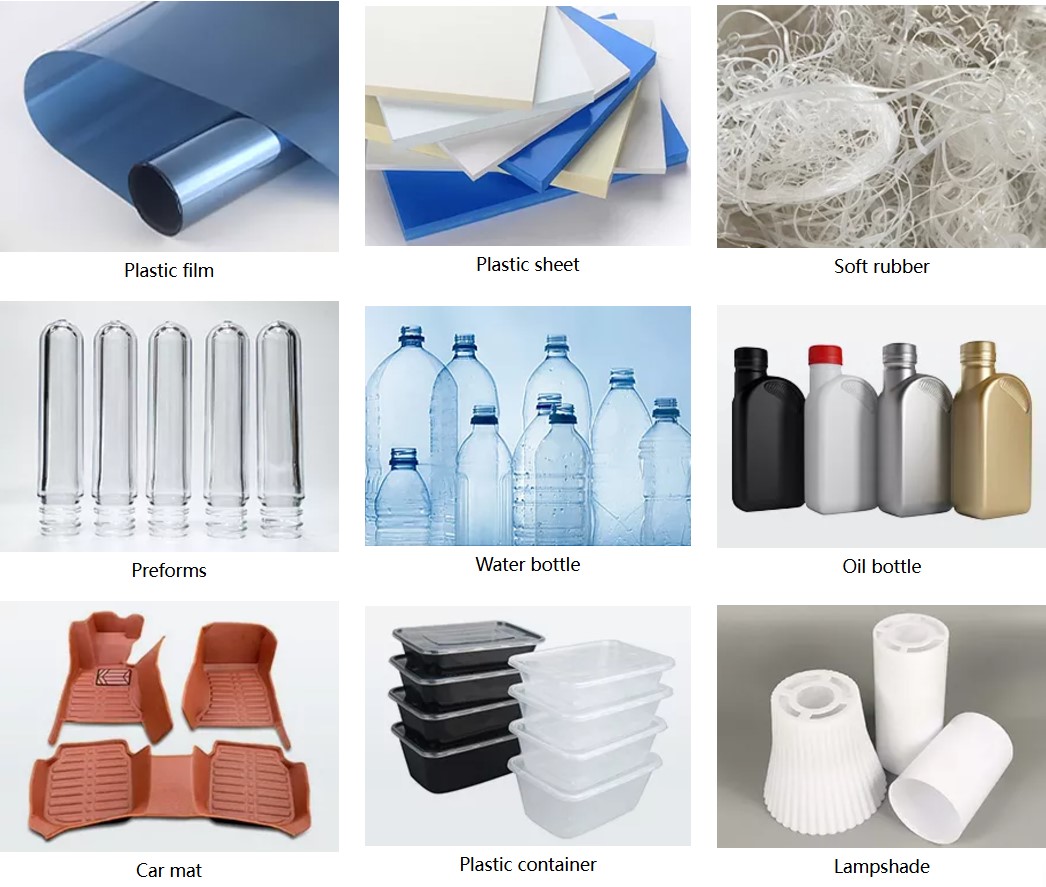

| Crushing Process Material

The design and tool configuration of the GD Flat-Type Plastic Crusher make it particularly suitable for the following types of plastic products:

1. Blow-molded parts: This includes bottle preforms, plastic bottles, oil bottles, soy sauce bottles, and other blow-molded products.

2. Sprues and runners: These are plastic edge materials or cutting waste generated during the production process.

3. Thin products: Examples include plastic films, plastic bags, plastic sheets, and similar items.

The machine can also be customized for crushing PA66/PA6+20%-50%GF materials, which can significantly improve the machine's lifespan.

| Specifications of GD Series

|

Model |

XC-GD10HP |

XC-GD15HP |

XC-GD20HP |

XC-GD30HP |

XC-GD50HP |

XC-GD75HP |

XC-GD100HP |

|

|

XC-GD10HP-SP |

XC-GD15HP-SP |

XC-GD20HP-SP |

XC-GD30HP-SP |

XC-GD50HP-SP |

XC-GD75HP-SP |

XC-GD100HP-SP |

||

|

Grinding Chamber(mm) |

360x260 |

420x280 |

480x330 |

660x350 |

720x500 |

910x820 |

1050x820 |

|

|

Grinding Capacity (KG/H) |

170-340 |

255-420 |

300-460 |

420-680 |

680-1000 |

700-1200 |

850-1400 |

|

|

Stationary Cutter |

2 |

2 |

2 |

4 |

4 |

4 |

4 |

|

|

Rotary Cutter |

6 |

6 |

6 |

9 |

9 |

12 |

12 |

|

|

Mesh Size (mm) |

10 |

10 |

10 |

12 |

12 |

12 |

12 |

|

|

Power |

KW |

7.5 |

11 |

15 |

22 |

37 |

55 |

75 |

|

HP |

10 |

15 |

20 |

30 |

50 |

75 |

100 |

|

|

Dimensions (LxWxHxH1 mm) |

1000x830x 1270x960 |

1200x995x1 540x1215 |

1300x1075x 1725x1350 |

1500x1330x 1880x1480 |

2000x1535x 2470x1914 |

2420x1050x 3300x2460 |

2420x2065x 3320x2460 |

|

|

Approx. Net Weight (KG) |

540 |

800 |

1023 |

1723 |

2750 |

5400 |

6250 |

|

|

Dimension for SP (mm) |

1250x880x 1500x1190 |

1420x1020x 1760x1440 |

1500x1140x 1920x1540 |

1750x1400x 2140x1735 |

2150x1570x 2770x2200 |

2630x1985x 3560x2720 |

2630x2080x 3560x2720 |

|

|

Collective Blower (KW) |

2.2 |

2.2 |

2.2 |

3 |

4 |

5.5 |

7.5 |

|

|

Approx. N.W for SP (KG) |

750 |

1180 |

1 |

|||||

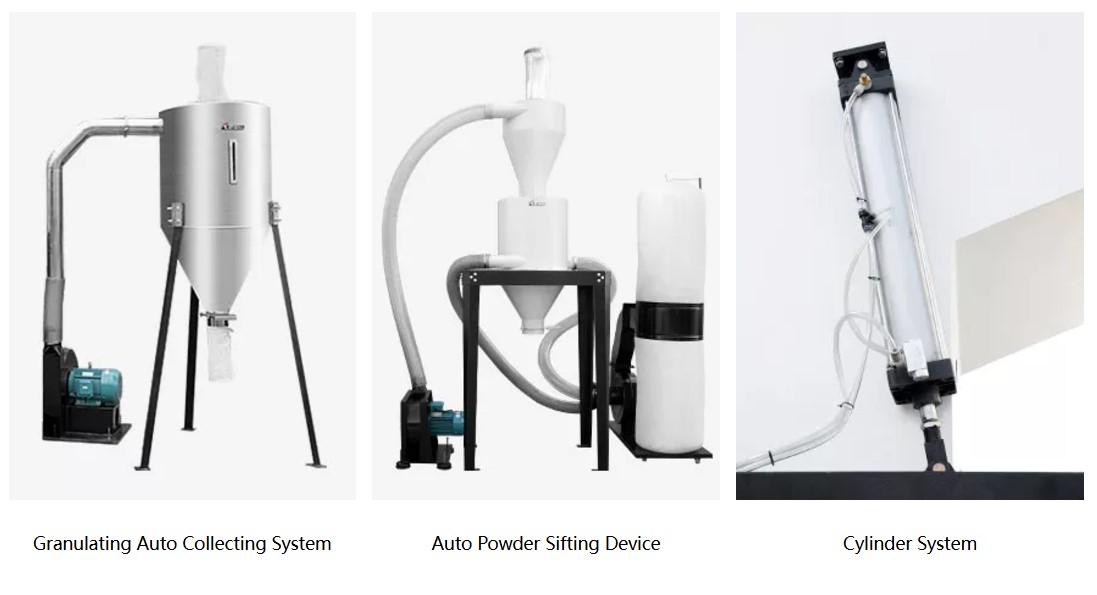

Optional Accessories List

The standard GD crusher offers optional configurations of an automatic recycling and automatic powder screening system. This system can automatically recycle the crushed material, reducing the need for manual operation and thereby improving production efficiency. For models with 75HP or higher, the feeding hopper and screen frame are equipped with a cylinder system, which is included as standard. For other models, you have the option to add this cylinder system based on your requirements.