GB Series Plastic Granulator

16 ธันวาคม 2567

ผู้ชม 108 ผู้ชม

Product Description

GB Plastic Bottle Crusher

The Xiecheng GB series plastic bottle crusher, also known as plastic bottle granulator, is a plastic crusher designed specifically for processing hollow plastic products. This machine is mainly suitable for processing various hollow plastic containers, such as hollow bottles and hollow barrels. Whether it is square or round PC/PET hollow blow-molded barrels, it can be crushed directly without the need for manual cutting, avoiding material bouncing. Additionally, this crusher features low power consumption and high efficiency, making it widely used in the recycling and reuse of waste plastics and the processing of non-conforming products.

| Features of the GB Plastic Bottle Crusher

-

Unique patented design of the front blade, eliminating the need for manual cutting and enabling direct crushing.

-

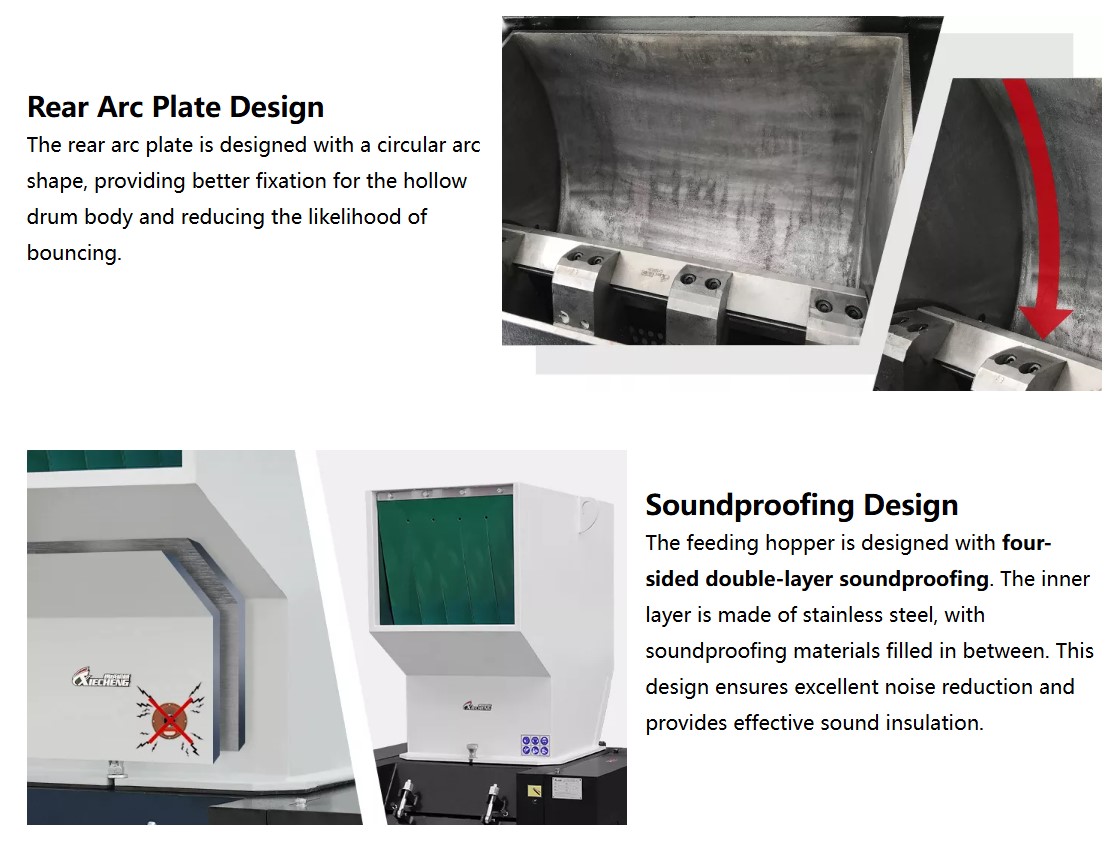

Four-sided double-layer soundproofing design for the feeding hopper, providing excellent noise reduction.

-

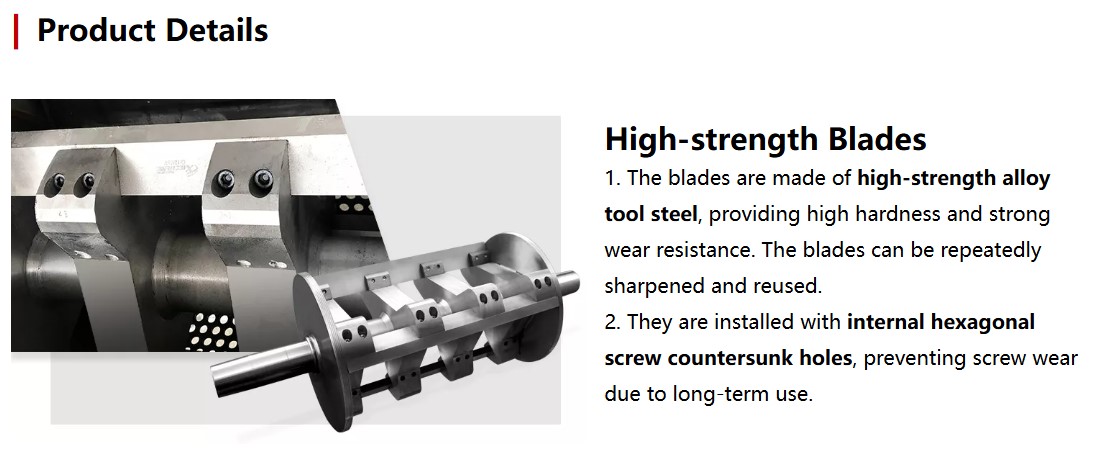

The blades are made of high-strength alloy tool steel, which ensures high hardness and strong wear resistance. The blades can be repeatedly sharpened and reused.

-

Installed with internal hexagonal screw countersunk holes, preventing screw wear due to long-term use.

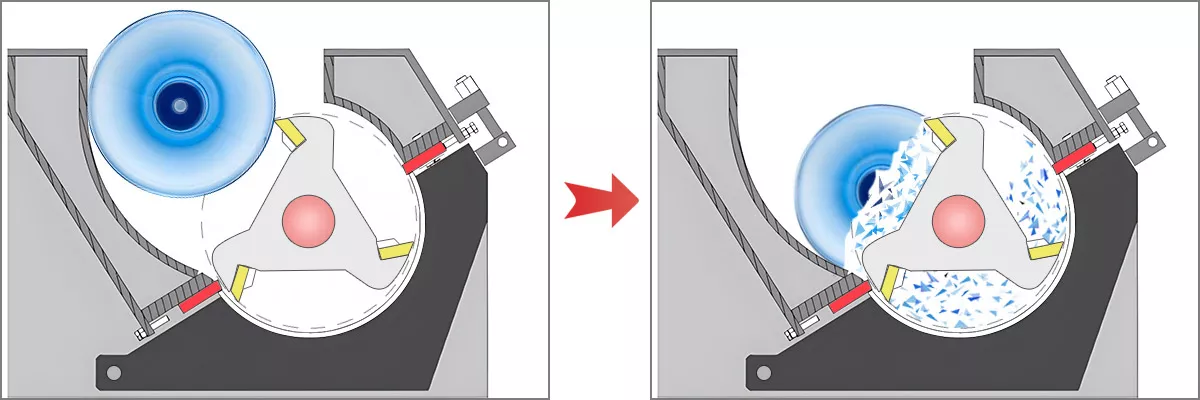

The Xiecheng GB plastic bottle crusher features a unique front blade design specifically tailored for hollow bottles and hollow drums, utilizing patented technology. The design forms a V-shaped angle between the rotating blade and the fixed blade, allowing the crushed material to be effectively guided into the center of the rotating blade. This design offers a larger cutting angle, resulting in a more efficient crushing process. Additionally, it achieves uniform and consistent crushing, minimizing the generation of powder during operation.

| Video of GB Series Crusher

| Standard Specifications of GB Series

| Model | XC-GB20HP | XC-GB30HP | XC-GB50HP | XC-GB75HP | |

| Grinding Chamber (mm) | 530*400 | 660*450 | 830*520 | 1100*740 | |

| Grinding Capacity (KG/H) | 300-550 | 400-550 | 750-1080 | 800-1200 | |

| Stationary Cutter | 2 | 4 | 4 | 4 | |

| Rotary Cutter | 3 | 6 | 6 | 9 | |

| Mesh Size (mm) | 14 | 14 | 16 | 16 | |

| Power | KW | 15 | 22 | 37.5 | 55 |

| HP | 20 | 30 | 50 | 75 | |

| Dimensions (LxWxHxH1 mm) | 1430×1120×1930×1458 | 1430×1120×1930×1458 | 2000x1610x2690x2030 | 2450x1940x3460x2710 | |

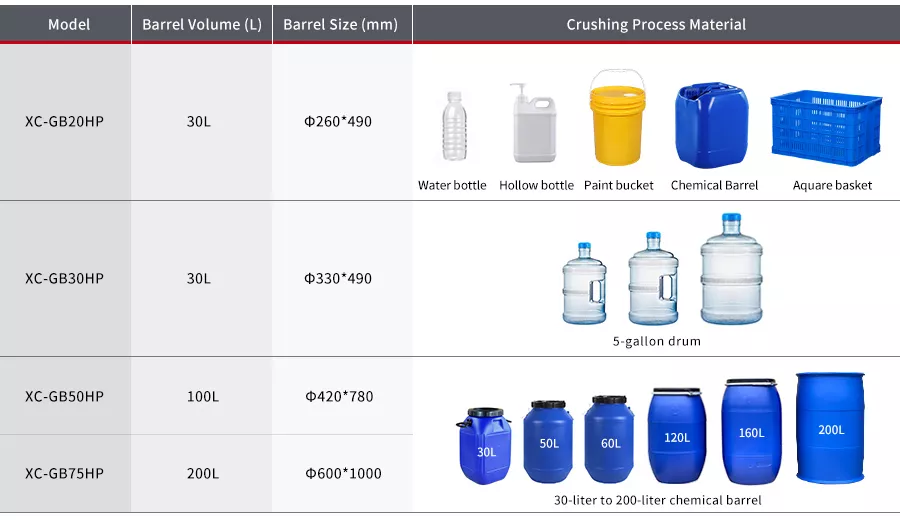

| Barrel Volume (L) | 30L | 30L | 100L |

200L |

|

| Barrel Size (mm) | Φ260*490 | Φ330*490 | Φ420*780 |

Φ600*1000 |

|

Optional Accessories List

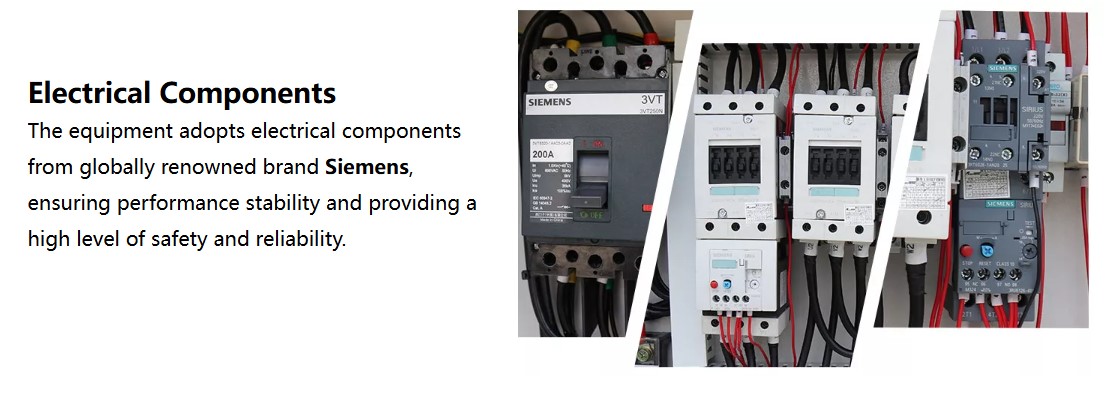

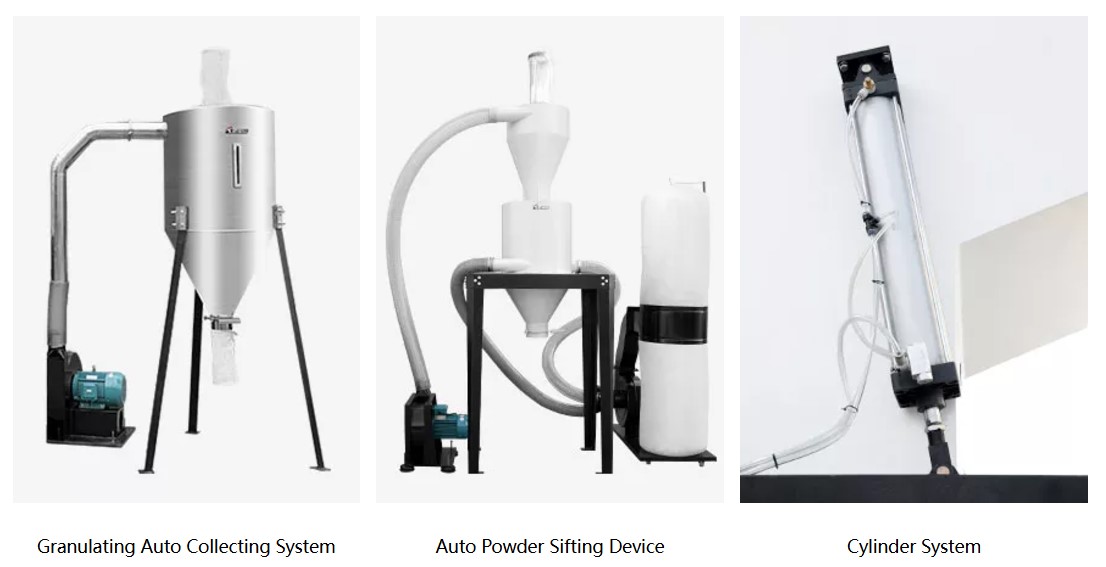

The standard GB plastic bottle crusher offers optional configurations for an granulating auto collecting system and an auto powder sifting device. This system automatically recycles the crushed material, reducing the need for manual handling and improving production efficiency. For models with a power rating of 75HP and above, the feeding hopper and screen mesh frame are equipped with a cylinder system, which is included as standard. For other models, you have the option to add the cylinder system.

The Crushing Effect

The Xiecheng GB Plastic bottle crusher machine is widely used in the rubber and plastic industry, including bottle blowing machines and blow molding machines. It is capable of directly crushing various shapes of hollow blow-molded barrels, including square and round PC/PET hollow blow-molded barrels, as well as mineral water bottles, gallon drums, paint buckets, chemical barrels, and more of various sizes. Additionally, this bottle crusher exhibits outstanding processing capability, with the ability to directly crush hollow barrels of up to 200 liters in size.