Volumetric Ratio of Two Feed Mixer

13 ธันวาคม 2567

ผู้ชม 119 ผู้ชม

product description

Volumetric Ratio of Two Feed Mixer

Mainly utilized for mixing with certain proportion of raw material and recycled material, or two different types raw materials.

Product Details

|

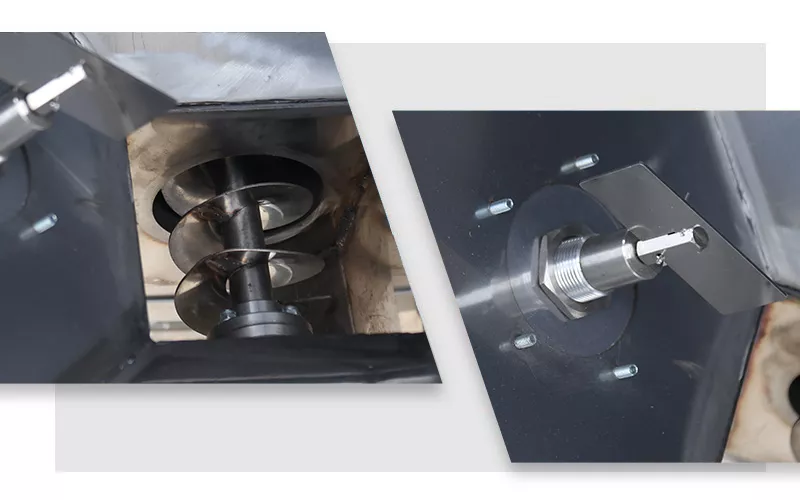

Barrel PartSUS201 barrel part ensures no contamination on raw materials |

Hopper DesignStorage barrel divided as Hopper 1 and Hopper 2; Each hopper could be mounted with vacuum receiver or self-contained loaders. |

|

|

Volumetric Screw Dosing DevicesEquipped with two sets of volumetric screw dosing devices for accuracy of material providing; Default with level sensor, buzzer and lamp alarm for material shortage alerting. |

Screw MaterialWith stainless steel made screws to keep consistency of raw materials |

|

|

Suction BoxDefault with suction box for connection with auto loader |

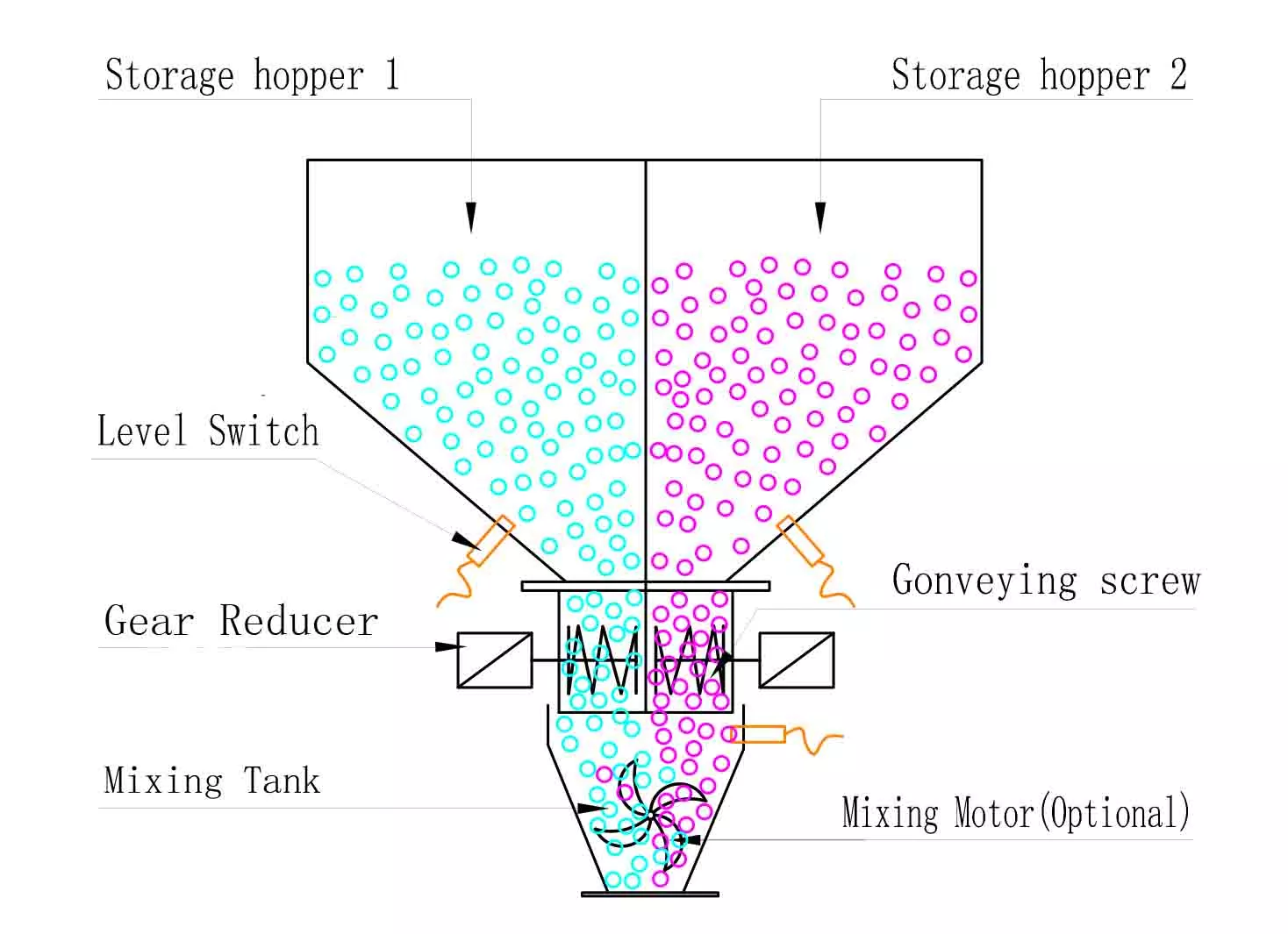

Structure Diagram

|

Working Principle

After material loaded in hoppers, set the speed ratio of materials. Switch to 1#/2# and turn on power, the geared motor drives the screw and feeds material into mixing chamber. When level switch at mixing chamber detects full loaded, the screw stops feeding and the mixing motor (optional) delay-stops. When material in short the geared motor automatically runs again and release material |

Specifications

| Model | Screw motor power(W) | Mixing motor power(W) | Screw diameter(mm) |

1#Hopper Capacity(L) |

2#Hopper Capacity(L) |

Max capacity(kg/hr) |

Tube diameter(inch) |

Dimensions(mm) W*D*H*H1 |

| XC-VTM50-160U | 60+60 | 90 | 50 | 80 | 80 | 480~850 | 1.5~2.5 | 710*710*1090x197 |

| XC-VTM50-320U | 160 | 160 | 810*810*1420x197 | |||||

| XC-VTM70-720U | 90+90 | 70 | 360 | 360 | 800~1450 | 1010*1010*1530x197 | ||

| XC-VTM70-1200U | 600 | 600 | 1210*1210*1750x197 |