product description

VOLUMETRIC DOSER

XCM series volumetric dosers are adaptable to auto-proportion mixing of new materials, regrinds, masterbatch or additives, adaptable to injection, extrusion or blow molding field. A stepper motor is used in this series, according to the set mixing proportion, the microprocessor accurately controls rotation of the high precise dosing screw to squeeze out materials with an deviation of ±1%. This volumetric doser can connect with various molding machine signals in synchronicity, to ensure the stability of the products.

Advantages of Volumetric Doser:

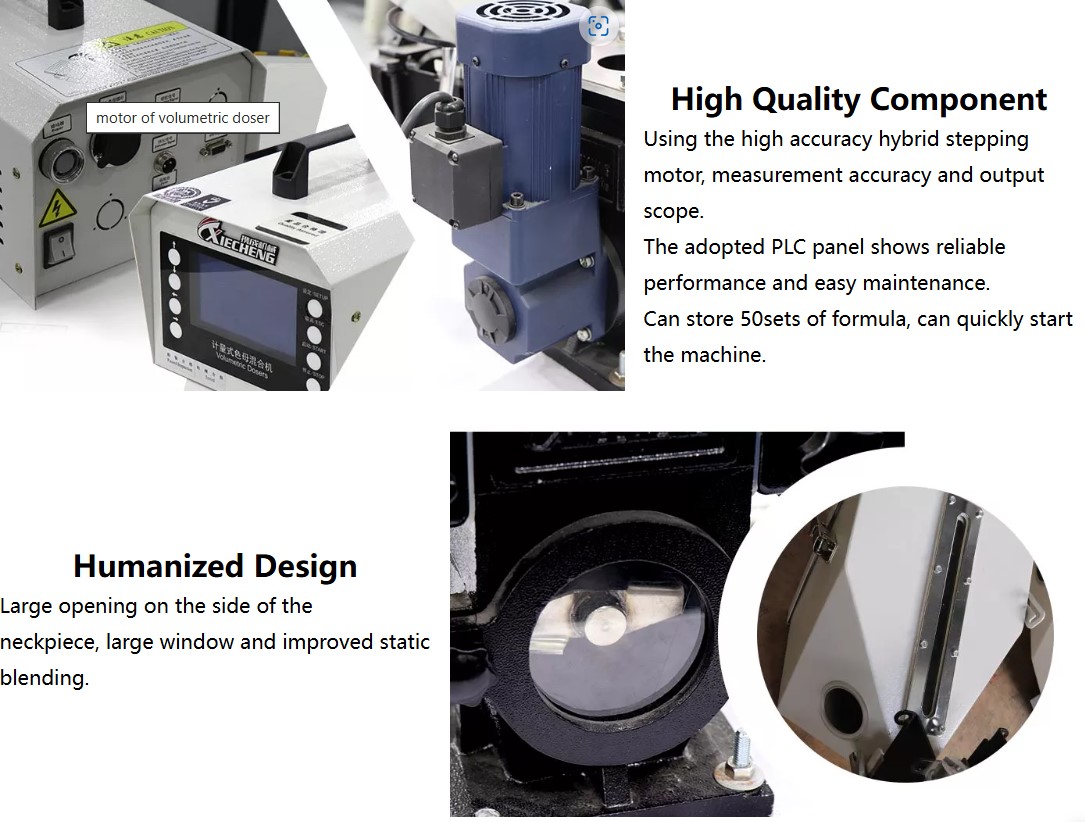

1. It is adopted with the stepping motor that can accurate the output volume;

2. The PLC controller takes accurate calculation of color batch or addictive proportions;

3. It allows up to 50 permanent recipes that can be reused at any time;

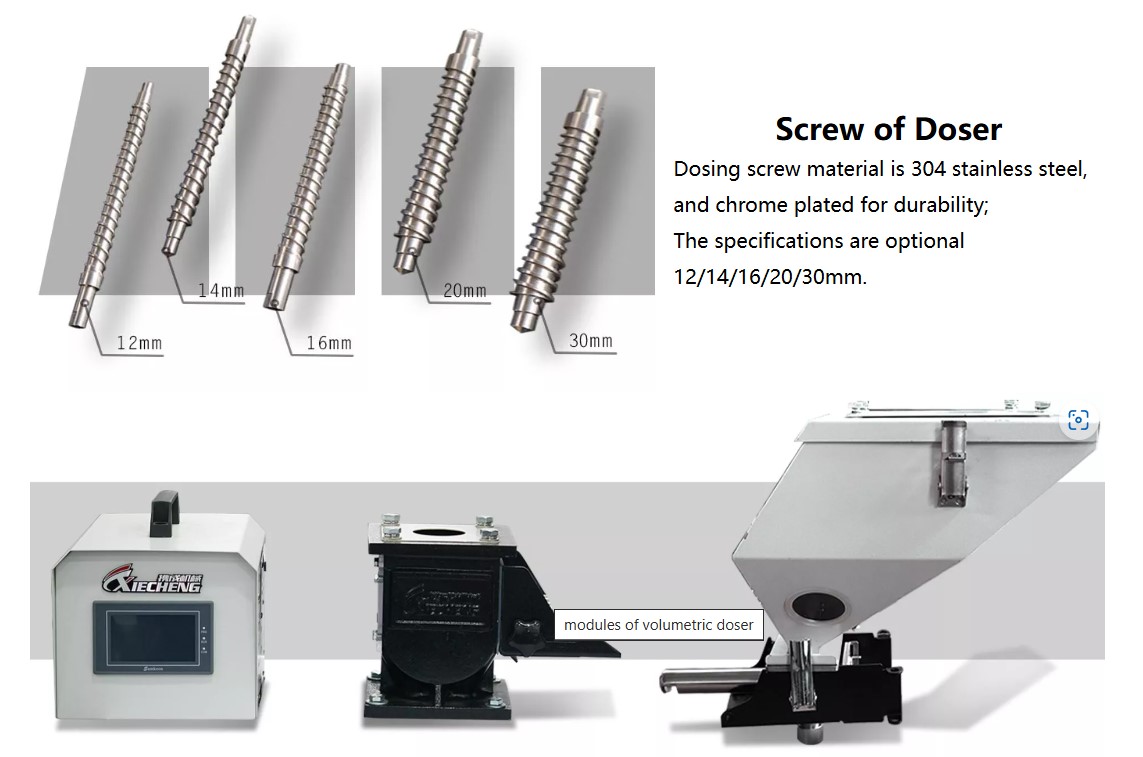

4. The screw is made of the durable stainless steel 304;

5. The module structural design makes it even handy for installation, cleaning and parts replacement;

6. Accommodated with both injection and extrusion condition.

Volumetric Doser Introduction Video:

Youtube: https://youtu.be/2GfbWnWW2Q0

Product Details

Detachable Modules

Unit is comprised of standard modules for ease of cleaning, disassembly and interchangeability;

The roof-shaped quick-change(the dosing section can be removed without granulate leaking form the neckpiece).

Structure Diagram

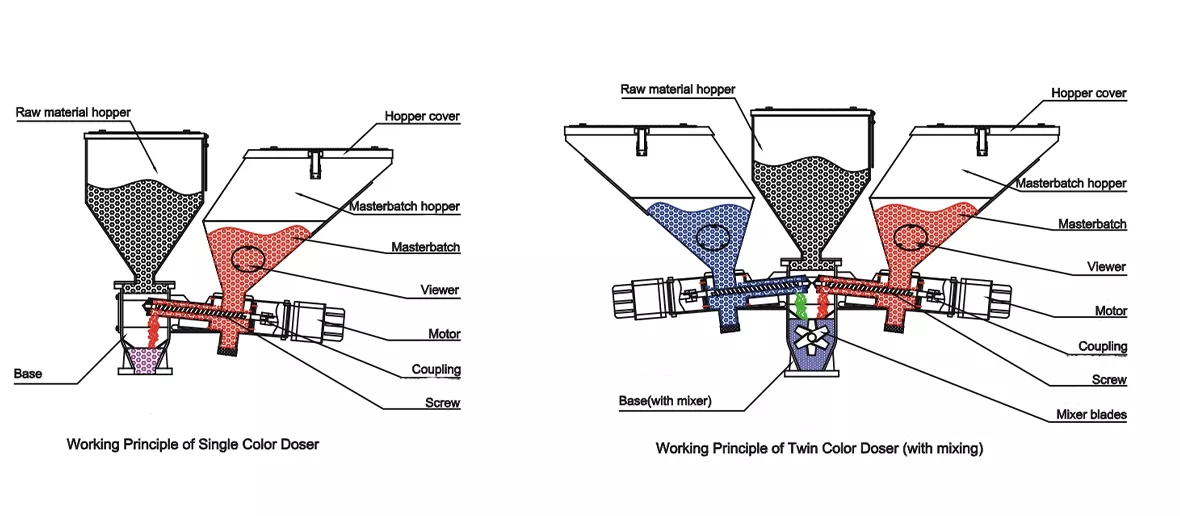

Working Pronciple of Volumetric Doser :

| Model | Monochrome Machine | Two-color Machine | Three-color Machine | ||

| XCM-12 | XCM-14 | XCM-16 | XCM-D2 | XCM-D3 | |

| Motor Power (Kw) | 0.3 | 0.3 | 0.3 | 0.3x2 | 0.3x3 |

| Rotary Speed (r.p.m.) | 1.8~300 | 1.8~300 | 1.8~300 | 1.8~300 | 1.8~300 |

| Mixer Power (Kw) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Screw Dia. (mm) | 12 | 14 | 16 | ** | ** |

| Output Capacity (kg/hr) | 0.05~20 | 0.1~40 | 0.5~64 | * | * |

| Sorage Capacity (L) | 13 | 13 | 13 | 13 | 13 |

| Main Raw Material Hopper (L) | Optional | Optional | Optional | Optional | Optional |

| Mixer Power (Kw) | Optional | Optional | Optional | Optional | Optional |

| Floor Stands | Optional | Optional | Optional | Optional | Optional |

| Dimensions | |||||

| H(mm) | 430 | 430 | 430 | 430 | 430 |

| W(mm) | 560 | 560 | 560 | 1010 | 1010 |

| D(mm) | 300 | 300 | 300 | 300 | 560 |

| Net Weight (kg) | 25 | 25 | 25 | 45 | 75 |

|

Small base size(mm) |

150x120x95x100x52xM8x180xR6xR17 | ||||

| Small bass mixing size(mm) | 150x120x95x100x52xM8x280xR6xR17 | ||||

| Large base size (mm) | 230x180x130x**x90x**x300x110xR8.5x** | ||||

| Large bass mixing size(mm) | 230x180x130x**x90x**x350x110xR8.5x** | ||||