product description

Standard Separate Vacuum Hopper Loader X810G

The XC-X810G separate vacuum hopper loader features a design that separates the main unit from the material hopper, enhancing flexibility. It comes standard with a magnetic induction material hopper, allowing for adjustable directions of the hopper and base according to customer needs. This series employs an inductive high-pressure fan characterized by strong suction, low noise, and a long lifespan. It is suitable for conveying various plastic materials during the production and processing of plastic molding.

| Feature:

- Main machine separated from the hopper, easy and safe to operate.

- Independent filter and transparent shell are easier to observe dust accumulation in filter barrel, clean up in time and guarantees machine work properly;

- LCD microcomputer controller with adjustable parameters is easy and convenient to operate;

- Motor has overload automatic protection, alarm for material shortage and automatically removing dust function;

- Equipped with Independently controlling material-cutting suction box, proportional valve and vacuum breaking valve function;

- Optional RS485 communication function can achieve remote automatic management;

- Model: XC-X810G, XC-X810G2 are equipped with magnetic vacuum hopper in standard version.

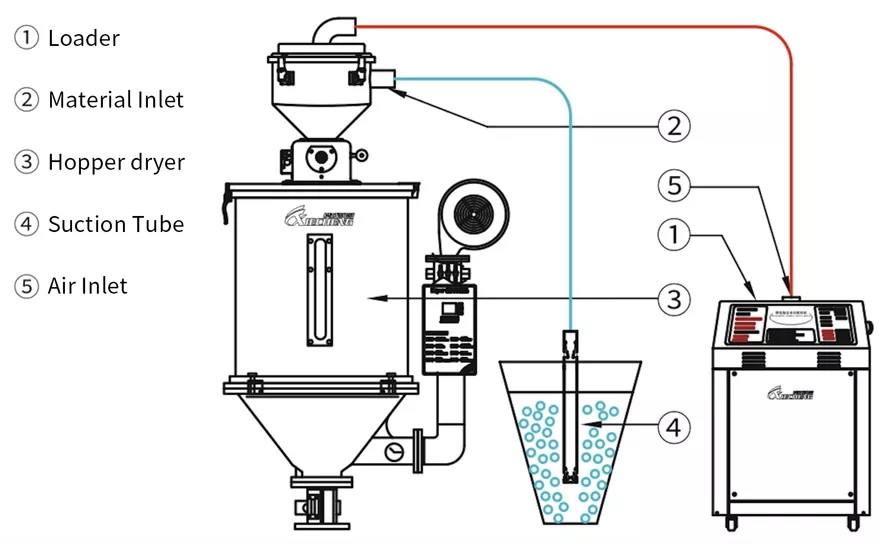

| Installation Diagram

| Product Details

|

Filter

|

|

Microcomputer Controller

|

|

|

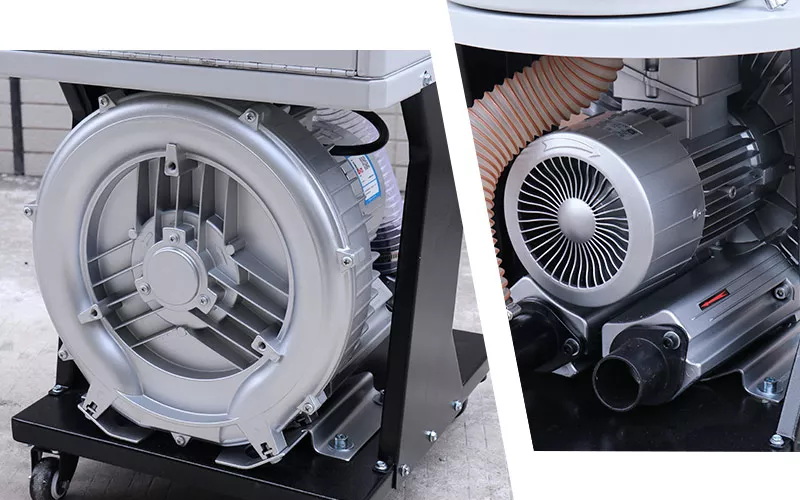

Induction Motor

|

|

Magnetic Hopper Utilizes magnetic reed switch control for sensitive induction and smoother operation. |

|

| Specifications

|

Model |

XC-X810G |

XC-X810G2 |

|

|

Motor |

Type |

Induction |

Induction |

|

Specification |

1.1kw/1.5hp 3φ |

1.5kw/2hp 3φ |

|

|

Conveying capacity(kg/hr) |

450 |

500 |

|

|

Loading distance(m) |

4 |

5 |

|

|

Static wind pressure(mm/H2O) |

1800 |

2400 |

|

|

Reservoir volume(L) |

7.5 |

7.5 |

|

|

Conveying tube inner diameter(mm) |

φ38 |

φ38 |

|

|

Specification of the attached hoses |

φ38mm×8m 1pc |

φ38mm×10m 1pc |

|

|

Dimensions(cm) |

Main frame |

45x38x67 |

45x38x67 |

|

Hopper |

38x28x45 |

||

|

Approx. Net weight (kg) |

48 |

48.5 |

|