Die Casting Oil Mold Temperature Controller

16 ธันวาคม 2567

ผู้ชม 98 ผู้ชม

Product Description

Die Casting Oil Mold Temperature Controller

The Die-casting Oil Mold Temperature Controller, also known as a oil type special temperature control units for die casting, is a specialized mold temperature control device for die-casting machines. Through a heat-conductive oil circulation system, it delivers heat to the mold's surface, thereby achieving precise mold temperature control. It can reach a maximum operating temperature of 320 degrees with stable operating temperatures. With a well-designed dual-circuit oil output system, it can independently control the temperatures of the moving mold and the fixed mold, ensuring the best conditions for die-casting product formation. It is widely used in the die-casting processes of alloys such as aluminum and zinc, effectively improving efficiency, stability, and casting quality in the die-casting production process and can be used with various mold types and materials.

| Product Features

• All series adopts magnetic drive pump to prevent oil leakage;

• Adopt 10-inch super large touch screen human-computer interaction, real-time temperature curve query, paperless massive date export;

• With SUS304 stainless steel seamless pipe, can ensure corrosin-resistant, no oil leakage and durable;

• Protection functions including pump over-temperature protection, power-on exhaust, power-off automatic cooling, low water pressure alarm etc.

• With maintenance and replacement reminders for wearing parts and consumables;

• Power output is adjustable;

• 7.With RS485 communication function, can realize network communication and centralized monitoring.

• 8.Equipped with one-button automatic oil return function.

| Product Video

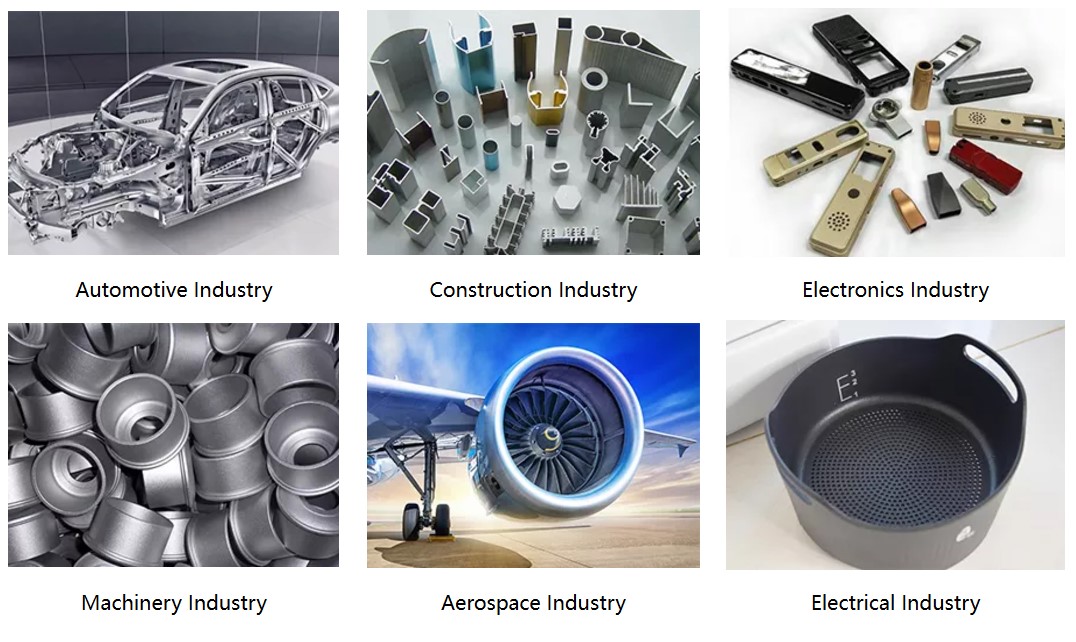

| Industry Applications

Die-casting mold temperature machines are widely employed in the die-casting industry and casting production in various sectors, including automotive, electronics, machinery, construction, electrical, aerospace, and more. In the automotive industry, they play a significant role in the casting production of components such as automobile engines, transmissions, chassis, and body parts. In the electronics industry, they are used to manufacture products such as TV casings, air conditioner housings, computer enclosures, and more. In the machinery industry, they are extensively used in the production of various machine tool components, hydraulic elements, and other products. In the construction industry, these machines are instrumental in the production of items like doors, windows, pipes, and steel components.

Specifications

|

Model |

Unit |

XC-DCO 24KW2S-320 |

XC-DCO 36KW2S-320 |

XC-DCO 48KW2S-320 |

XC-DCO 24KW-320 |

XC-DCO 36KW-320 |

XC-DCO 48KW-320 |

|

Temperature Control Range |

℃ |

320℃ |

|||||

|

Temperature Control Accuracy |

℃ |

P.I.D ±0.1℃ |

|||||

|

Power |

AC 3φ/380v/50Hz |

||||||

|

Heat Transfer Medium |

Heat Transfer Oil |

||||||

|

Cooling Method |

Indirect Cooling |

||||||

|

Heating Capacity |

KW |

24x2 |

36x2 |

48x2 |

24 |

36 |

48 |

|

Pump Power |

KW |

1.1x2 |

2.2x2 |

3x2 |

1.1 |

2.2 |

3 |

|

Max. Pump Flow |

(L/min) |

60x2 |

90x2 |

140x2 |

60 |

60 |

140 |

|

Max. Pump Pressure |

(kg/cm2) |

2.5x2 |

3x2 |

3x2 |

2.5 |

2.5 |

3 |

| Booster Pump Head | m | 40x2 | 70x2 | 70x2 | 40 | 40 | 70 |

|

Oil Tank Capacity |

Liter |

60 |

60 |

60 |

50 |

50 |

50 |

|

Alert Function |

Phase Loss/Oil Shortage/Over-Heat/Overload |

||||||

|

Cooling Water Pipe |

mm |

3/4 |

1/2 |

||||

|

Inlet Outlet Diameter |

Inch |

3/4x2 |

1"x2 |

1"x2 |

3/4x2 |

1"x2 |

1"x2 |

|

Dimension (L*W*H) |

mm |

1350x600 x1300 |

1350x600 x1300 |

1350x600 x1300 |

1020x510 x880 |

1020x510 x880 |

1020x510 x880 |

|

Approx. Net Weight |

KG |

280 |

280 |

280 |

210 |

210 |

210 |