Product Description

COLD AND HOT TEMPERATURE CONTROLLERS

Industrial Chiller Series

FEATURE:

1. Easily to shift quickly from cooling and heating process with one-press operation based on production needs, temperature control maintains within +2°C

2. High efficient evaporator and condenser could save energy consumption more than 30%

3. With sufficient protections, intelligent fault indication and buzzer alarm, which is high-automatized and requires no dedicated human operations.

| Working Principle

When the air cooled chiller starts, the refrigerant absorbs the heat from the cooled object in the evaporator and vaporizes. The compressor continuously extracts the generated gas from the evaporator and compresses it into high-temperature, high-pressure vapor. The refrigerant vapor is then sent to the condenser, where it undergoes heat exchange with the air. After releasing heat, it condenses into a liquid. The liquid refrigerant, after being depressurized by the expansion valve, enters the evaporator where it vaporizes again, absorbing heat from the cooled object. This heat exchange process is repeated until the industrial water is cooled to the desired temperature.

| ① | Compressor | ⑨ | Temp. sensor |

| ② | Condenser | ⑩ | Water tank |

| ③ | Dry filter | ⑪ | Pump pressure gauge |

| ④ | Expansion valve | ⑫ | Pump |

| ⑤ | Evaporator | ⑬ | By-pass valve |

| ⑥ | Ball valve | ⑭ | Low pressure switch |

| ⑦ | Anti-freezing switch | ⑮ | High pressure switch |

| ⑧ | Level sensor | ⑯ | Blower |

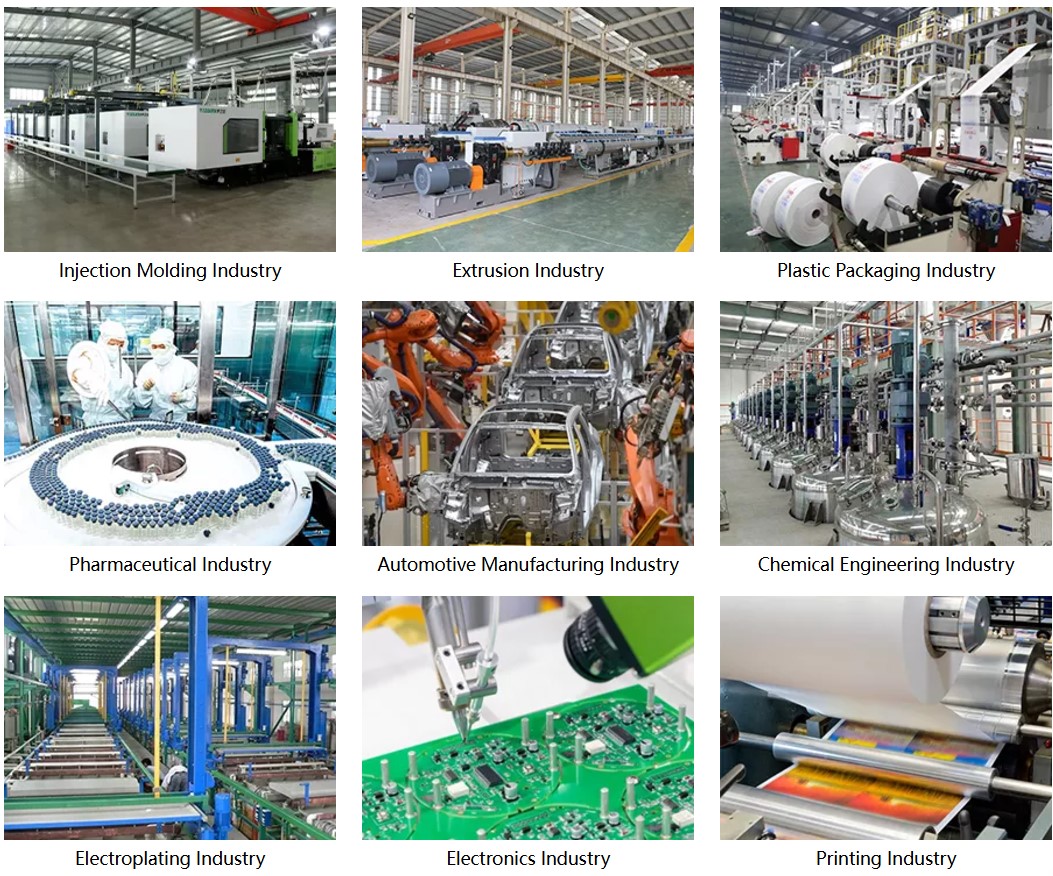

| Application Scope in the Industry

Chillers are widely used in various industrial productions such as plastics, electronics manufacturing, electroplating, pharmaceuticals, chemical engineering, ultrasonic cooling, and printing. They are employed in the cooling of molds for plastic processing machinery, significantly improving the surface smoothness of plastic products, reducing surface flaws and internal stress, preventing shrinkage and deformation, facilitating mold release, accelerating product shaping, and thus greatly enhancing the production efficiency and product quality of plastic molding machines.

| Highlights of the Product

Scroll Compressor

The entire range of Xiecheng air cooled chillers utilizes scroll compressors. The compressor serves as the heart of the entire refrigerant cycle system. The scroll compressor adopts a dual-flex design, ensuring tight sealing between the scroll discs. This design allows the scroll discs to separate radially and axially, allowing debris or liquid to pass through without damaging the compressor. This results in increased compressor lifespan, enhanced reliability, better liquid tolerance, and improved tolerance for impurities.

|

|

|

|

1. Dual-flex design: The compressor features a dual-flex design, ensuring flexibility and reliability in operation. |

|

| Shell and Tube Evaporator

The air cooled chiller utilizes a shell and tube evaporator. In this system, the refrigerant evaporates inside the heat exchange tubes, while water flows on the shell side. To enhance the heat exchange efficiency, a 2mm thick baffle plate is installed on the shell side, causing the water to flow back and forth to create ice brine. Additionally, to maintain a stable operating temperature, the exterior shell of the evaporator is covered with insulation material.

For the heat exchange tubes, we employ high-efficiency seamless copper tubes. These tubes undergo a grooving process to form internal thread fins, thereby increasing the heat exchange surface area with the refrigerant. With this technology, the heat transfer area is doubled, significantly improving the heat transfer efficiency.

| Finned Type Condenser

By adopting a high-efficiency copper tube with aluminum finned type condenser, the air cooled chiller effectively dissipates heat. The finned structure increases the heat exchange surface area between the condenser and the surrounding environment, improving the heat dissipation efficiency. The excellent thermal conductivity of copper tubes, combined with the efficient heat dissipation characteristics of aluminum fins, ensures high efficiency during the cooling process.

Additionally, the application of light water aluminum and blue aluminum foils provides an additional protective layer. They help prevent corrosion of the copper tubes in corrosive environments, thereby extending the lifespan of the condenser and maintaining optimal refrigeration performance.

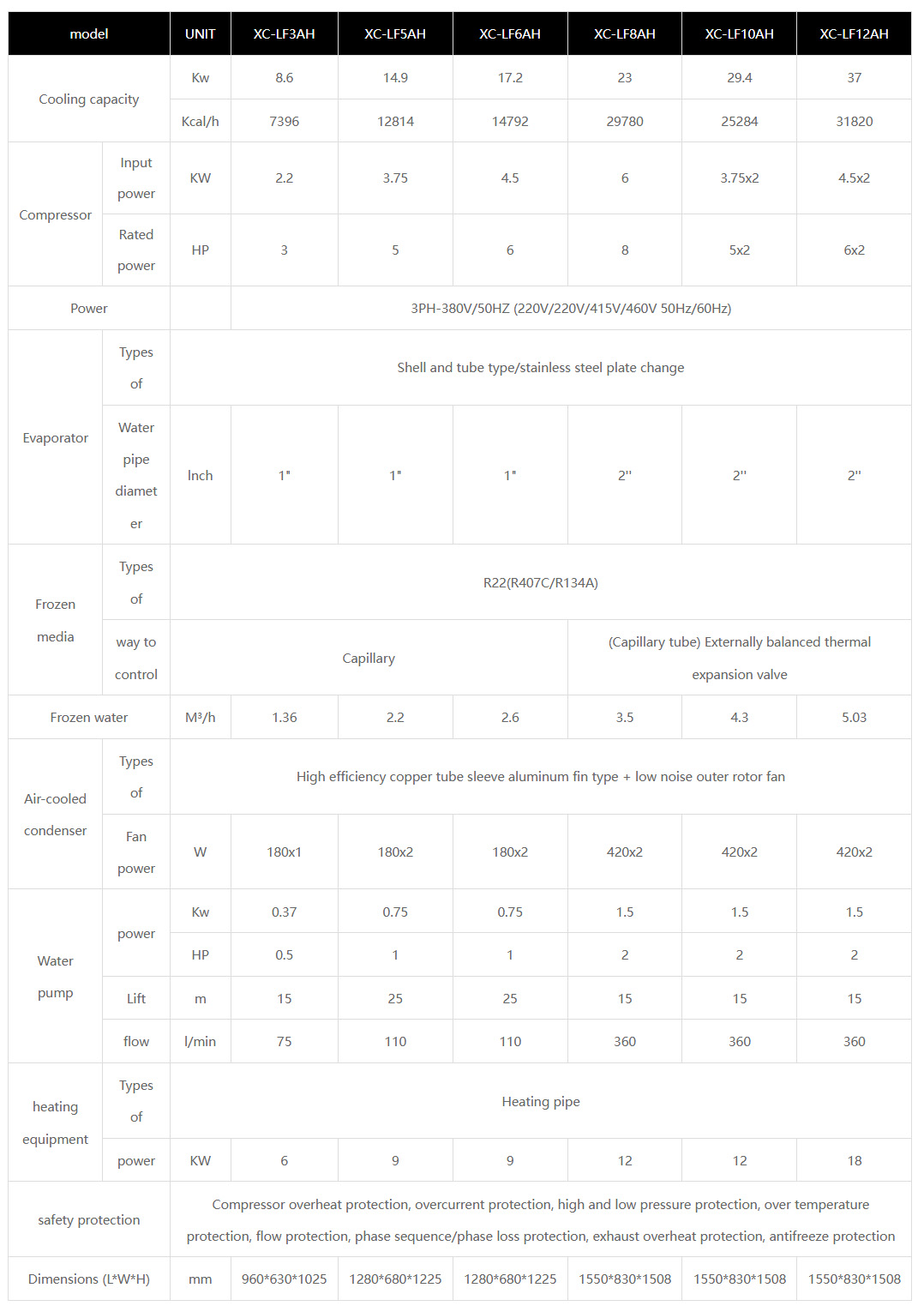

| Specifications