Product Description

Water Cooled Chiller

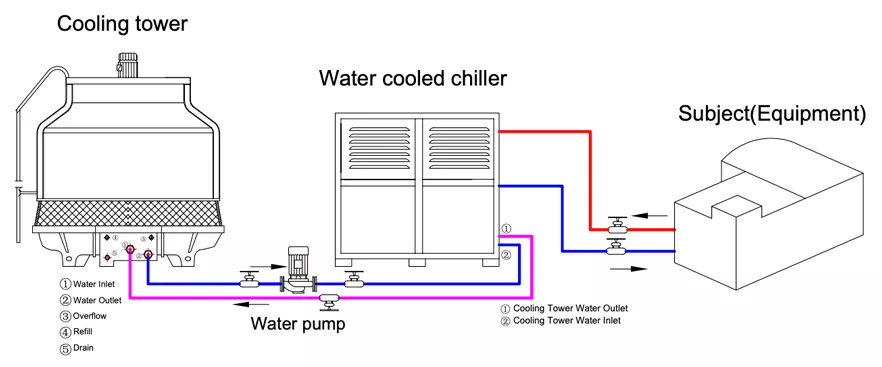

Water Cooled Chiller, also known as packaged water cooled chiller or water cooling chiller, is an efficient and reliable industrial cooling equipment. It dissipates heat through the circulation of cooling water and requires connection to a cooling tower or cooling device to exhaust the generated heat. Compared to air cooled chillers, water cooled chillers typically offer higher cooling efficiency and lower noise levels. Additionally, they provide flexible capacity and specification options to meet different process requirements.

The refrigeration range of water cooled chillers is extensive, ranging from 2967 Kcal/h to 139664 Kcal/h, and they can provide chilled water with a temperature range of 3°C to 50°C. This makes them an ideal choice for optimizing production efficiency and ensuring production quality.

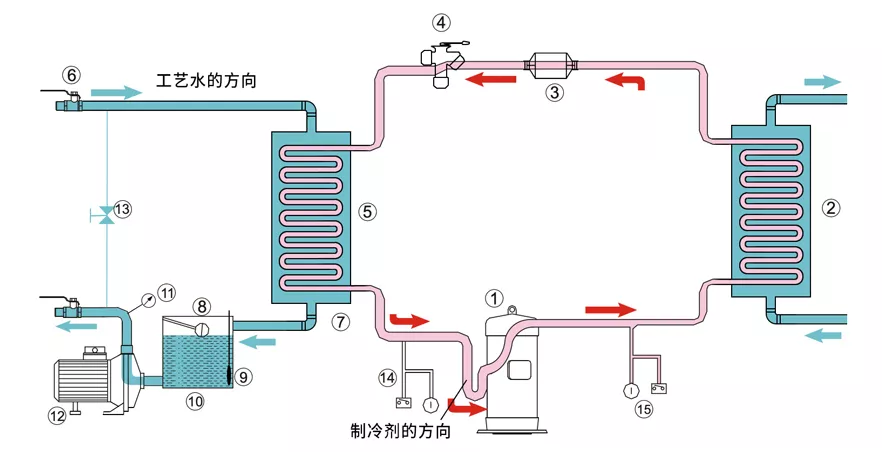

A water-cooled chiller utilizes a shell and tube evaporator to facilitate heat exchange between water and refrigerant. The refrigerant system absorbs the heat load from the water, causing the water to cool and generate chilled water. The heat absorbed by the refrigerant is then transported to the shell and tube condenser through the action of the compressor. Heat exchange occurs between the refrigerant and water, allowing the water to absorb the heat. Finally, the heat is dissipated to the external cooling tower through water pipes, which is known as water cooling.

| ① | Compressor | ⑨ | Temp. sensor |

| ② | Condenser | ⑩ | Water tank |

| ③ | Dry filter | ⑪ | Pump pressure gauge |

| ④ | Expansion valve | ⑫ | Pump |

| ⑤ | Evaporator | ⑬ | By-pass valve |

| ⑥ | Ball valve | ⑭ | Low pressure switch |

| ⑦ | Anti-freezing switch | ⑮ | High pressure switch |

| ⑧ | Level sensor | ⑯ | Blower |

| Application Scope in the Industry

Chillers are widely used in various industrial productions such as plastics, electronics manufacturing, electroplating, pharmaceuticals, chemical engineering, ultrasonic cooling, and printing. They are employed in the cooling of molds for plastic processing machinery, significantly improving the surface smoothness of plastic products, reducing surface flaws and internal stress, preventing shrinkage and deformation, facilitating mold release, accelerating product shaping, and thus greatly enhancing the production efficiency and product quality of plastic molding machines.

Injection Molding Industry |

Extrusion Industry |

Plastic Packaging Industry |

|

Pharmaceutical Industry |

utomotive Manufacturing Industry |

Chemical Engineering Industry |

|

Electroplating Industry |

Electronics Industry |

Printing Industry |

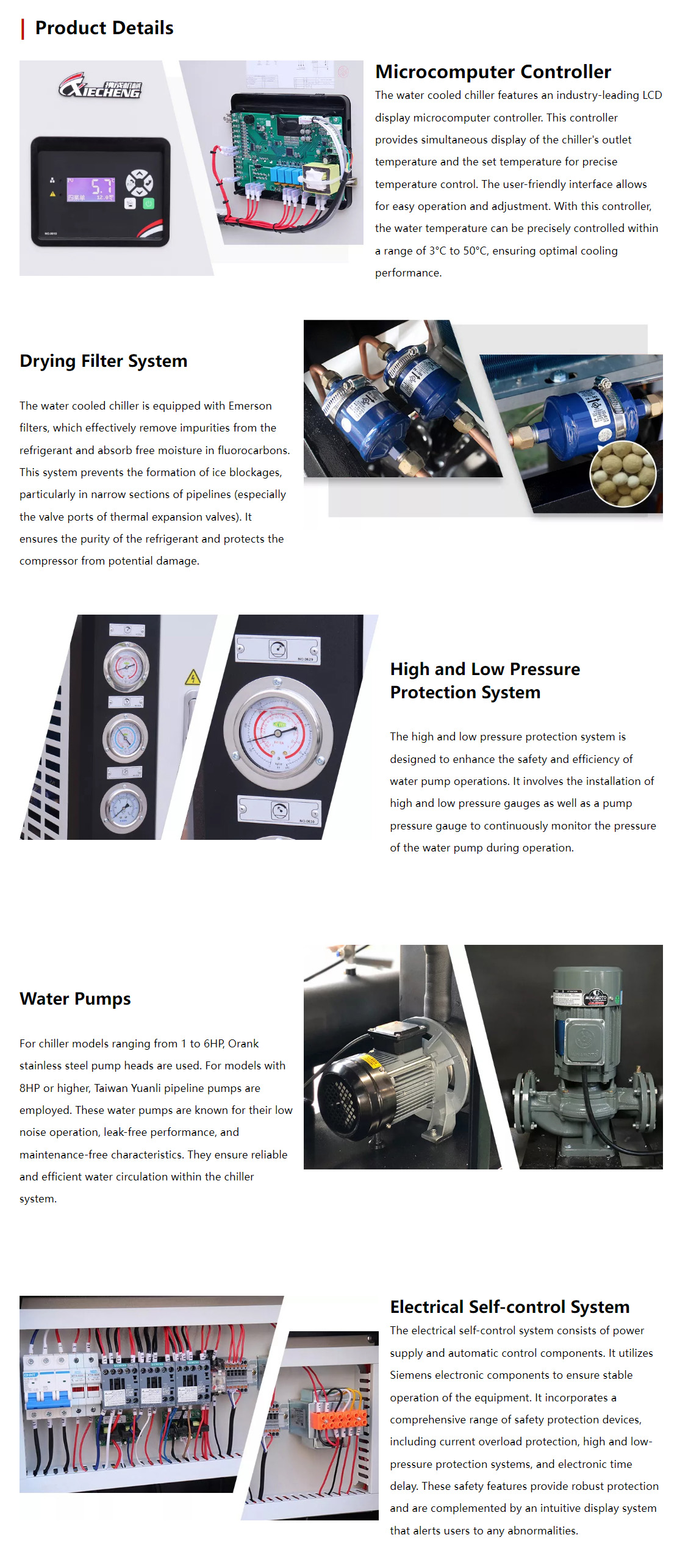

| Highlights of the Product

Scroll Compressor

The entire range of Xiecheng water cooled chillers utilizes scroll compressors. The compressor serves as the heart of the entire refrigerant cycle system. The scroll compressor adopts a dual-flex design, ensuring tight sealing between the scroll discs. This design allows the scroll discs to separate radially and axially, allowing debris or liquid to pass through without damaging the compressor. This results in increased compressor lifespan, enhanced reliability, better liquid tolerance, and improved tolerance for impurities.

|

|

|

|

1. Dual-flex design: The compressor features a dual-flex design, ensuring flexibility and reliability in operation. |

|

| Shell and Tube Evaporator

The water cooled chiller utilizes a shell and tube evaporator. In this system, the refrigerant evaporates inside the heat exchange tubes, while water flows on the shell side. To enhance the heat exchange efficiency, a 2mm thick baffle plate is installed on the shell side, causing the water to flow back and forth to create ice brine. Additionally, to maintain a stable operating temperature, the exterior shell of the evaporator is covered with insulation material.

For the heat exchange tubes, we employ high-efficiency seamless copper tubes. These tubes undergo a grooving process to form internal thread fins, thereby increasing the heat exchange surface area with the refrigerant. With this technology, the heat transfer area is doubled, significantly improving the heat transfer efficiency.

| Shell and Tube Condenser

Water Cooled Chiller utilizes a shell and tube condenser, with the internal copper tubes employing an outer thread embossing process. This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.