product description

GRAVIMETRIC BLENDER

The Gravimetric Blenders of Xiecheng are used in injection, extrusion and blowing production with more than one materials by different proportional mixture.

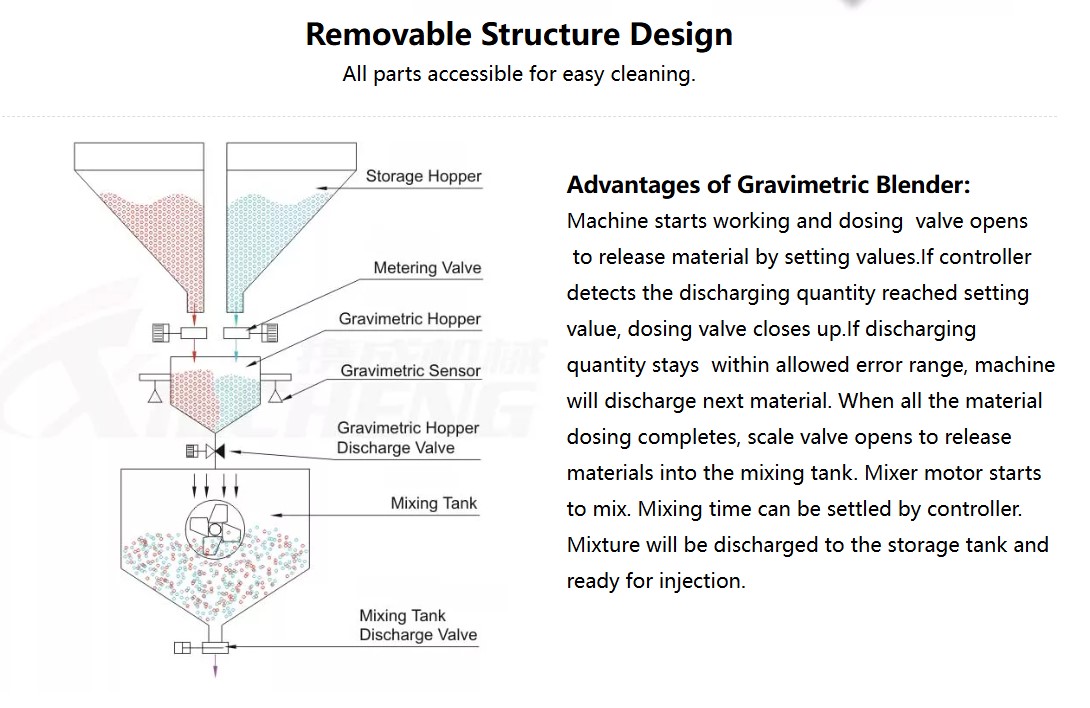

Advantages of Gravimetric Blender:

1. Suitable for processing up to four components simultaneously;

2. Adopting advanced control algorithm,autonomous optimization,automatic calibration and shaking prevent function,ensure the best accruracy;

2.Color chart shown,touch screen operation,three languages on-line switching;

3. Up to 100recipes can be stored for later use;

4. Multilevel password protection and historical alarm record;

5. Can be directly mounted on the machine or optional feet frame installed in machine side.

Gravimetric Blender Introduction Vedio:

Youtube: https://youtu.be/4FeAiFZcXj4

Product Details

Specifications

Parameters of Gravimetric Blender:

| Model | XGB-50 | XGB-100 | XGB-200 | XGB-400 | XGB-600 |

| Qty of Group Number | 4 | 4 | 4 | 4 | 4 |

| Mixing capacity(kg/hr) | 50 | 100 | 200 | 400 | 600 |

| Batch weight (kg) | 1.5 | 3 | 4 | 6 | 8 |

| Main material mixing range (%) | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 |

| Additive mixing range (%) | 0.5~10 | ||||

| Main hopper volume (L) | 20x2 | 30x2 | 40x2 | 45 | 70 |

| Additive hopper volume (L) | 10x2 | 15x2 | 20x2 | 15 | 18 |

| Mixing tank volume (L) | 25 | 50 | 50 | 80 | 80 |

| power supply (V/Hz) |

200~240V/50~60HZ/1P |

220~460V/50~60HZ/3P | |||

| Total power (kw) | 0.12 | 0.12 | 0.25 | 0.55 | 0.55 |

| Compressed air (kgf/cm2) | 4~6 | ||||

| Max. noise level (dB) | <75 | <75 | <75 | <75 | <75 |

|

Machine installation (H0xWxD)(mm) |

1010x600x620 | 1350x650x560 | 1400x700x650 | 1588x760x660 | 1738x850x700 |

|

Stand Frame installation (HxWxD)(mm) |

1565×600×620 | 1820×650×560 | 1870×700×650 | 2115×760×660 | 2265×850×700 |

| Base (mm) (H2xW2xD2 ) |

170*(120~140)*80*6 |

150*(100~120)*89*6 |

150*(100~120)*89*6 |

180*(105~140)*100*7 |

180*(105~140)*100*7 |

| Stand (mm) (H1xW1xD1) |

560*710*560 | 600*725*555 | 660*725*555 | 730*705*535 | 730*705*535 |

| Net weight (kg) (machine installation) |

90 | 90 | 130 | 140 | 180 |

| Net weight (kg) (floor installation) |

110 | 110 | 155 | 165 | 230 |

| Model | XGB-800 | XGB-1200 | XGB-2000 | XGB-2500 | XGB-3000 |

| Qty of Group Number | 4 | 4 | 4 | 4 | 4 |

| Mixing capacity (kg/hr) | 800 | 1200 | 2000 | 2500 | 3000 |

| Batch weight (kg) | 12 | 15 | 20 | 25 | 30 |

| Main material mixing range (%) | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 |

| Additive mixing range (%) | 0.5~10 | ||||

| Main hopper volume (L) | 100 | 130 | 160 | 180 | 230 |

| Additive hopper volume (L) | 25 | 30 | 40 | 50 | 70 |

| Mixing tank volume (L) | 110 | 110 | 150 | 150 | 150 |

| power supply (V/Hz) | 220~460V/50~60HZ/3P | ||||

| Total power (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Compressed air (kgf/cm2) | 4~6 | ||||

| Max. noise level (dB) | <75 | <75 | <75 | <75 | <75 |

|

Machine installation (H0xWxD)(mm) |

1870x900x900 | 1970x1000x900 | ------- | ------- | ------- |

|

Stand Frame installation (HxWxD)(mm) |

2375×900×900 | 2475×1000×900 | ------- | ------- | ------- |

| Base (mm) (H2xW2xD2 ) |

200*(110~140)*100*7 | 200*(110~140)*100*7 | ------- | ------- | ------- |

| Stand (mm) (H1xW1xD1) |

760*900*650 | 760*900*650 | ------- | ------- | ------- |

| Net weight (kg) (machine installation) |

200 | 250 | 280 | 290 | 380 |

| Net weight (kg) (floor installation) |

250 | 340 | 370 | 380 | 500 |