Product Description

All in One Compact Dryers

The XC-D series All In One Dehumidifying Dryer, also known as All In One Compact Dryers, is a honeycomb rotor dehumidifying dryer that combines drying, dehumidifying, and two-stage conveying functions in a single unit. The whole series are composed of a honeycomb rotor dehumidifier and a downward-blowing full stainless steel Euro hopper dryer and the dehumidifying dryer can provide a continuous supply of stable -40°C low dew point dry air for drying engineering plastics with strong moisture absorption properties. Its attractive appearance, stable performance, compact footprint, and easy mobility make it suitable for a variety of applications. The machine can be easily moved and the machine unit can be replaced, offering strong versatility and potential cost savings in equipment.

| Application Range

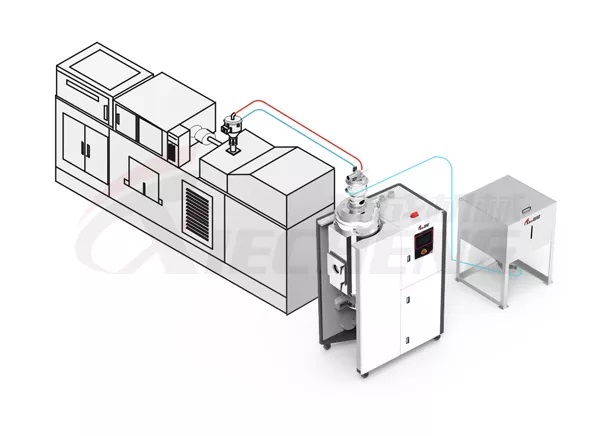

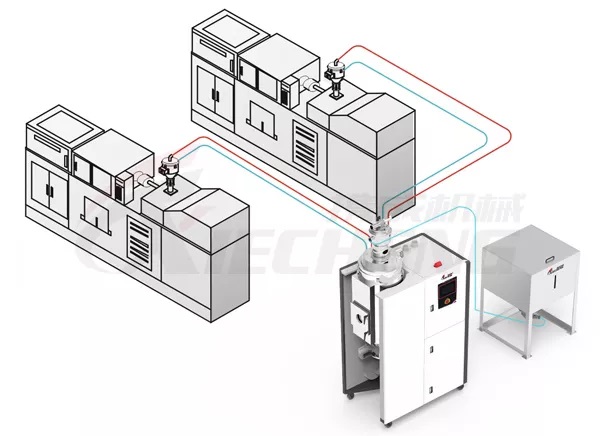

The All In One Dehumidifying Dryer is widely applicable to various plastic raw materials, particularly engineering plastics with strong moisture absorption properties, such as PA, PC, PBT, PET, and more. Depending on production requirements, it offers configurations with dual-stage conveying system (corresponding to one injection molding machine) or triple-stage conveying system (corresponding to two injection molding machines). This adaptability ensures efficient processing of moisture-sensitive materials, meeting the specific needs of different production scenarios.

|

For Servicing One Machine: Two-stage Conveying System(Standard) |

For Servicing Two Machine: Three-stage Conveying System(Optional) |

| Working Principle

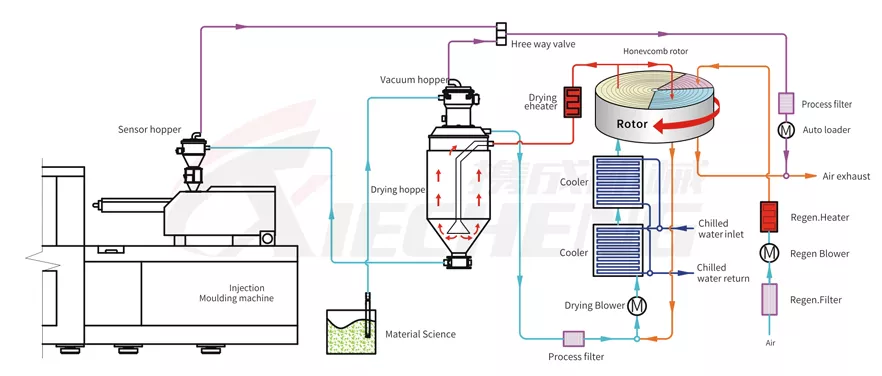

The purpose of the All In One Compact Dryer is to provide the drying hopper with stable low dew point dry air. The process begins with a vacuum hopper drawing plastic raw materials into the drying hopper. The humid and hot air returning from the drying hopper is cooled and blown into the honeycomb rotor. The moisture in the air is adsorbed by the rotor and subsequently desorbed by the heated regeneration air. Both airflows interact with the rotor simultaneously. As the rotor rotates, the moisture in the air is continuously adsorbed and desorbed by the regeneration air, resulting in the formation of stable low dew point air. This air is then heated to the drying temperature of the plastic and blown into the drying hopper, creating a sealed circulation for drying the raw materials. Finally, the dried materials are extracted from the drying hopper by a material suction fan and delivered to the photoelectric eye hopper installed on the plastic molding machine. This comprehensive process ensures effective drying of materials, facilitating their use in the plastic molding process.

| Highlights of the Product

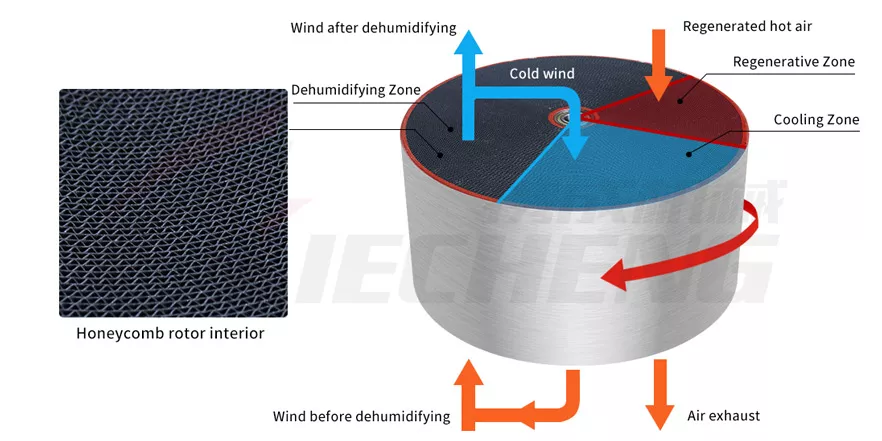

The dehumidification system is equipped with a honeycomb rotor.

The XCD model utilizes a honeycomb rotor that can continuously provide stable -40°C low dew point dry air, ensuring the high quality and stability of plastic molding products. It will not pollute the raw materials due to the aging of molecular sieve like a double-barrel molecular sieve dehumidifier.

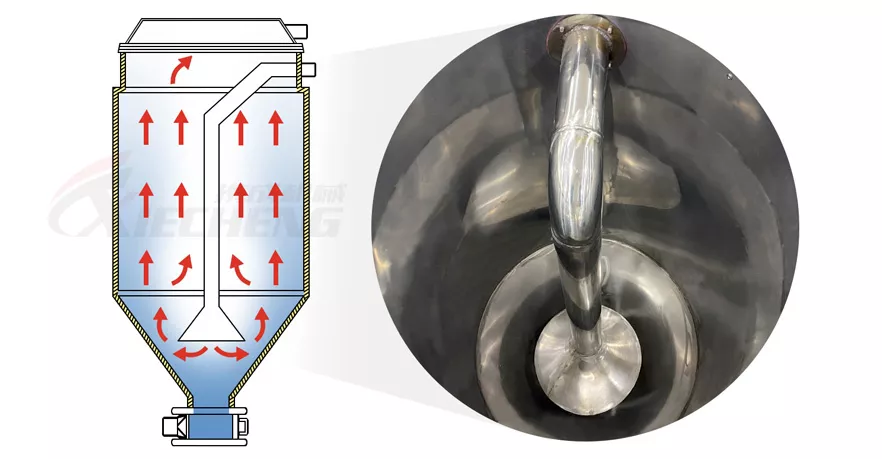

The drying system is complemented by a downward-blowing insulated drying hopper.

The insulated drying hopper features a design with a downward-blowing air duct and is paired with a cyclone exhaust device. This configuration prevents heat loss, maintains temperature, and enhances drying efficiency. All contact areas with the raw materials are constructed using stainless steel to ensure material purity and prevent contamination.

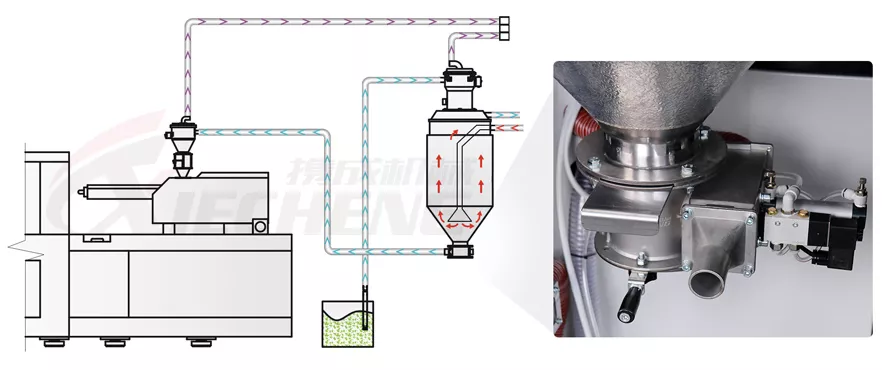

The conveying system is accompanied by a closed-loop vacuum loading.

All models are equipped with a closed-loop feeding system, which can prevent the dried raw materials from being damp again due to contact with outside air. Additionally, the feeding system is equipped with pneumatic shut-off valve to ensure no material remains in the material line after each loading cycle.

LCD display microcomputer controller

The All In One Dehumidifying Dryer is equipped with an LCD touchscreen human-machine interface for operation. This centralized interface provides convenience and offers temperature control precision of up to ±0.1°C. It also features a 24-hour timing function for scheduling automatic operation throughout the week. An optional dew point meter is available for real-time monitoring of dew point levels.

| Product Exterior

|

|

| Full-integral | Semi-integral |

| Specifications

|

Model |

XCD-40L/30H |

XCD-80L/50H |

XCD-120L/80H |

XCD-160L/120H |

XCD-230L/150H |

XCD-300L/200H |

XCD-450L/300H |

|

|

Drying system |

Drying System |

|||||||

|

Process Heater Power (kw) |

3 |

4 |

6 |

6 |

7.2 |

12 |

15 |

|

|

Process Blower Power (kw) |

0.4 |

0.4 |

0.75 |

0.75 |

1.5 |

2.2 |

3.75 |

|

|

Drying Hopper (L) |

80 |

120 |

160 |

230 |

300 |

450 |

||

|

Dehumidifier System |

Dehumidiying System |

|||||||

|

Regen. Heater Power (kw) |

3 |

3 |

3.5 |

3.5 |

4 |

5.4 |

7.2 |

|

|

Regen. Blower Power (kw) |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.75 |

|

|

Dry Air Capacity(m³/h) |

30 |

50 |

80 |

120 |

150 |

200 |

300 |

|

|

Conveying system |

Conveying System |

|||||||

|

Conveying Blower Power (kw) |

1.1 |

1.1 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

|

|

Dia. of Conveying Hose (inch) |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

2 |

2 |

|

|

Vacuum Hopper (L) |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

12 |

12 |

|

|

Sensor Hopper(L) |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

12 |

12 |

|

|

Demension |

Full-integral |

Semi-integral |

||||||

|

H(mm) |

1700 |

1720 |

1820 |

1910 |

1940 |

2100 |

2450 |

|

|

W(mm) |

1100 |

1100 |

1100 |

1320 |

1320 |

2000 |

2000 |

|

|

D(mm) |

710 |

710 |

710 |

900 |

900 |

1150 |

1150 |

|

|

Approx. Net Weight (kg) |

200 |

300 |

320 |

505 |

540 |

565 |

600 |

|

|

Model |

XCD-600L/400H |

XCD-750L/500H |

XCD-900L/700H |

XCD-1200L/700H |

XCD-1500L/1000H |

XCD-2300L/1500H |

XCD-3000L/2000H |

|

Drying system |

Drying System |

||||||

|

Process Heater Power(kw) |

18 |

18 |

24 |

30 |

32 |

38 |

48 |

|

Process Blower Power (kw) |

3.75 |

5.5 |

5.5 |

5.5 |

5.5 |

7.5 |

5.5x2 |

|

Drying Hopper Capacity (L) |

600 |

750 |

900 |

1200 |

1500 |

2300 |

3000 |

|

Dehumidifier System |

Dehumidiying System |

||||||

|

Regen. Heater Power (kw) |

7.2 |

10 |

10 |

10 |

15 |

18 |

24 |

|

Regen. Blower Power (kw) |

0.75 |

1.5 |

1.5 |

3 |

3 |

4 |

3x2 |

|

Dry Air Capacity(m³/h) |

400 |

500 |

700 |

700 |

1000 |

1500 |

2000 |

|

Conveying system |

Conveying system |

||||||

|

Conveying Blower Power (kw) |

1.5 |

2.2 |

2.2 |

5.5 |

5.5 |

7.5 |

7.5 |

|

Dia. of Conveying Hose(inch) |

2 |

2 |

2 |

2 |

2 |

2.5 |

2.5 |

|

Vacuum Hopper(L) |

12 |

12 |

24 |

24 |

24 |

24 |

24 |

|

Sensor Hopper(L) |

12 |

12 |

24 |

24 |

24 |

24 |

24 |

|

Demension |

Semi-integral |

||||||

|

H(mm) |

2450 |

2590 |

2600 |

3200 |

3500 |

3650 |

4250 |

|

W(mm) |

2200 |

2300 |

2400 |

2550 |

2900 |

3100 |

4000 |

|

D(mm) |

1150 |

1600 |

1650 |

1650 |

1450 |

1350 |

1900 |

|

Approx. Net Weight(kg) |

640 |

710 |

850 |

900 |

1160 |

1350 |

1950 |