Product Description

MOLD DEHUMIDIFIERS

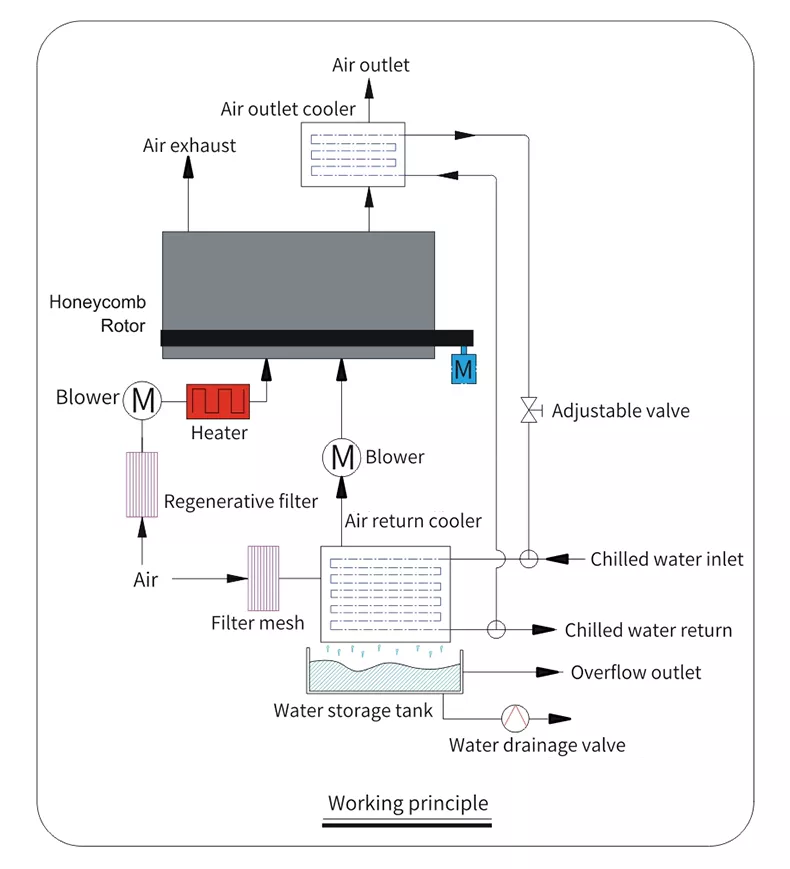

XC-MD series mold dehumidifiers are mainly applied in plastic molding, especially PET preform molding, to remove the moisture condensing issue on mold surface due to the use of chilled water for reducing molding cycle period. The issue occurs due to the temperature of mold surface is lower than the ambient and it would affect production guality and efficiency while harming the mold surfaces and even the environment. The series of mold dehumidifiers realize dehumidifying effect with honeycomb rotor and continuously provide low dew point dry air to the forming machines, hence the issue is prevented and the defect rate significantly reduced.

FEATURE:

1、LCD microcomputer controller monitoring regenerative and present temperatures;

2、Honeycomb rotorto provide constant full year dehumidified dry air;

3、Alarm function on motor overload and phase reverse;

4、Return air cooling and filtering are included.

5、Extending mold lifetime using, inhibiting corrosion and reducing insufficient issues and ratio;

6、Default with coolerat dryairoutletand availableto adjust temperature;

7、Automatic function on draining condensation water in time;

8、Optional for detachable return air collector to realize closed-loop air circulation, especially for regions with high humidity;

9、Optional for dew point monitor for easyobservation;

Through the honeycomb rotor moisture absorption, the air flow from drying blower reaches low dew point and directly goes to the mold of forming machine. The mold dehumidifier generated low dew point air makes the surrounding of mold very dry,usually dew point at 5 Celsius or lower. During rapid mold cooling, the surrounding air would quickly get cool but usually would not down to 5 Celsius,hence to keep cooling the mold without dewdrops occurring.

Specifications

|

型号 Model |

XC-MD1000H |

XC-MD2000H |

XC-MD3000H |

|

| Regenerative Heater(Kw) | 12 | 24 | 30 | |

| Regenerative Blower(Kw) | 0.37 | 0.55 | 0.75 | |

| Drying Blower(Kw) | 1.5 | 2.2 | 3.7 | |

| Dry Air Flow(M³/Hr) | 1000 | 2000 | 3000 | |

| Dry Air Tube(Inch) | 8 | 10 | 10 | |

| Regen.Air Tube(Inch) | 4 | 6 | 6 | |

| Cooler Outlet | 1.5” PT.5 | 1.5” PT | 2” PT | |

| Dry Air Temp.(℃) | ≤16 | ≤16 | ≤16 | |

| Dew Point(℃) | -10-+5 | -10-+5 | -10-+5 | |

| Cooling Water Flow(Lpm) | ≥100 | ≥150 | ≥190 | |

| Water Pressure(Kgf/cm²) | 1-5 | 1-5 | 1-5 | |

| Dimension(mm,H*W*D) | 1950*1000*1130 | 2350*1130*1300 | 2600*1300*1300 | |

| Approx.N.G.(Kg) | 321 | 580 | 700 | |